What You Need to Know About a Fogged IGU

In recent years, more and more people are choosing broken bridge aluminum alloy doors and windows for decoration. While enjoying the quietness and comfort, many friends have discovered why the glass of doors and windows at home is fogged up. How is this going? As an energy-saving building material, insulated glass is widely used because of its good thermal and sound insulation properties.

At the same time, the quality requirements for insulating glass are getting higher and higher. It is understood that the biggest quality problem of insulating glass is the condensation of the air layer during use, and the reason for the condensation of the air layer is that the dew point of the air layer increases during use.

Reasons for fogging and water leakage in insulating glass:

1. In the past, the old-fashioned plastic-steel double-glazed glass did not have the same technology as today. It simply combined two pieces of glass and used a double-sided seal in the middle. This material is not waterproof or sealed. When there is water vapor inside the window sash, Over time, it will evaporate into the double-layer glass, causing hazy water vapor inside the double-layer glass.

2. If this situation occurs in modern double-layer glass, it is only because the glass sealant around the glass is not tightly sealed or there are loopholes. Another possibility is that inferior glass sealant is used, and there are no other reasons that can cause such results.

3. The dew point of insulating glass refers to the temperature when the air humidity sealed in the air layer reaches a saturated state. Below this temperature, water vapor in the air layer condenses into liquid water. It can be deduced: that the higher the water content, the higher the dew point temperature of the air. When the temperature of the inner surface of the glass is lower than the dew point of the air in the air layer, the moisture in the air will condense or frost on the inner surface of the glass.

4. When the insulated glass window is installed, its construction technology is poor. After a certain period of use, the sealant cracks, causing water vapor to enter the interlayer of the insulated glass. As the temperature rises, the water vapor evaporates, when in contact with the glass surface, it turns into small water droplets, causing the double-layer glass to fog.

5. During the installation of double-layer insulated glass, due to the incomplete installation of the water tank inside, the water surface is higher than the profile, resulting in water flowing into the interlayer of the double-layer glass. Under the irradiation of sunlight, water vapor forms mist, causing the fogging phenomenon of double-layer glass.

How to control the dew point phenomenon of insulating glass?

(1) Strictly controlling the temperature of the production environment mainly affects the adsorption capacity and remaining adsorption capacity.

(2) Reducing the diffusion of moisture through the polymer mainly depends on selecting a sealant with a low permeability coefficient, determining a reasonable sealing thickness, and reducing the temperature difference between the inside and outside of the insulating glass (that is, controlling production within a certain temperature range without making the temperature range too large.)

(3) Reducing the production process time and minimizing the contact time between the desiccant and the atmosphere, reducing the loss of adsorption capacity and making the desiccant have higher adsorption capacity.

(4) Choose a suitable aluminum profile with a small pore air gap to reduce the water absorption rate of the molecular sieve during operation.

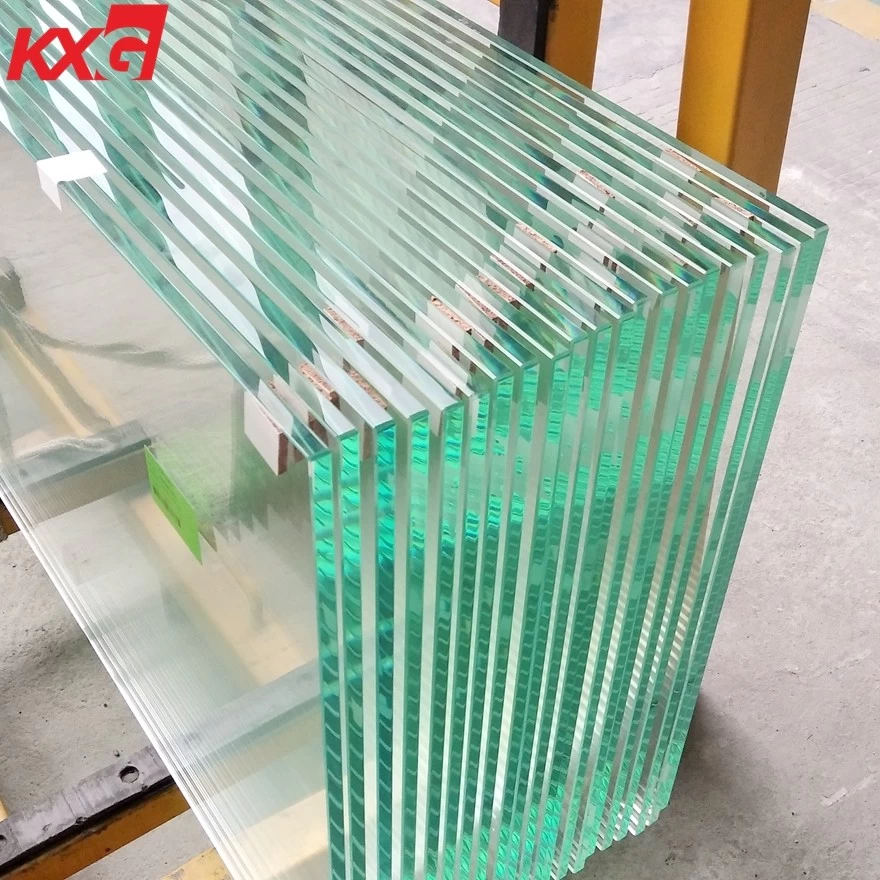

window door insulated glass wholesale

(5) When choosing a suitable desiccant, it is important to choose one with a high adsorption rate and long-lasting properties. I believe that through the control of various aspects such as material selection, processing, and environment, the quality of insulating glass will be significantly controlled.