- Browse Categories

- Curtain Wall Insulated Glass

- Showerdoor Tempered Glass

- Laminated Tempered Balustrade Glass

- Laminated Insulated Skylight Glass

- Doors and Windows Glass

- Clear Tempered Glass

- PVB SGP Safety Laminated Glass

- Safety Tempered Insulated Glass

- Silkscreen & Digital Printing Glass

- Tempered Curved Glass

- Heat Strengthened Glass

- Acid Etched Frosted Glass

- Heat Soaked Glass

- Colored Tinted Glass

- Heat Reflective Glass

- Table Top Tempered Glass

- Hot Products

-

8.76mm white laminated glass price,8.76mm white translucent laminated glass,obscure laminated glass factory

10mm 12mm 15mm safety toughened glass price,high quality tempered glass factory,safety toughened glass China

Wholesale 8mm 10mm ultra clear silk screen printing tempered glass,digital printing toughened glass price

Factory price decorative frameless curved tempered glass wall for shower,home bathroom glass wall panel

10mm bronze tinted tempered glass factory,10mm thickness bronze toughened glass,10mm bronze tempered glass price

- Certifications

-

- Subscribe

-

Get email updates on new products

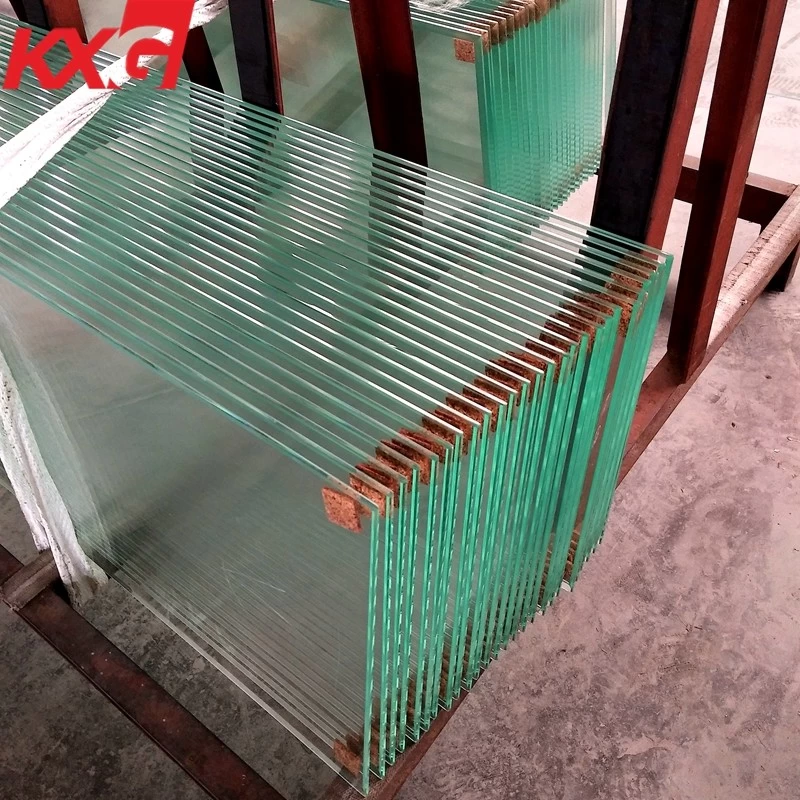

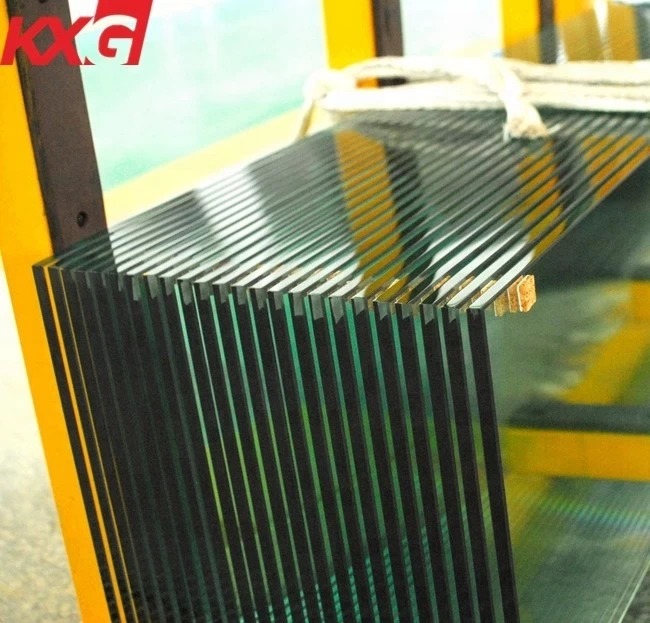

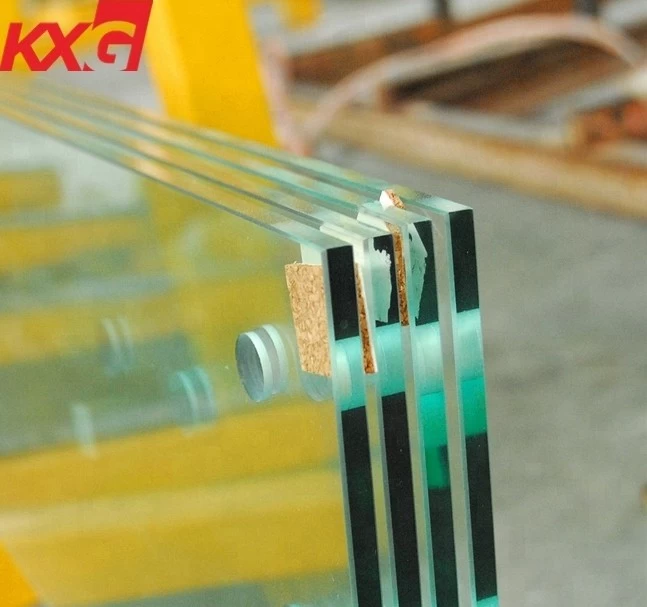

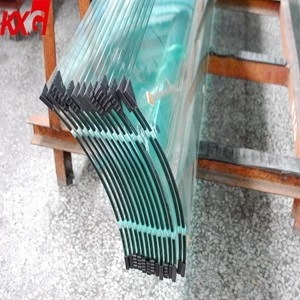

China heat soaked test glass factory heat soaked toughened ultra clear flat safety glass goods

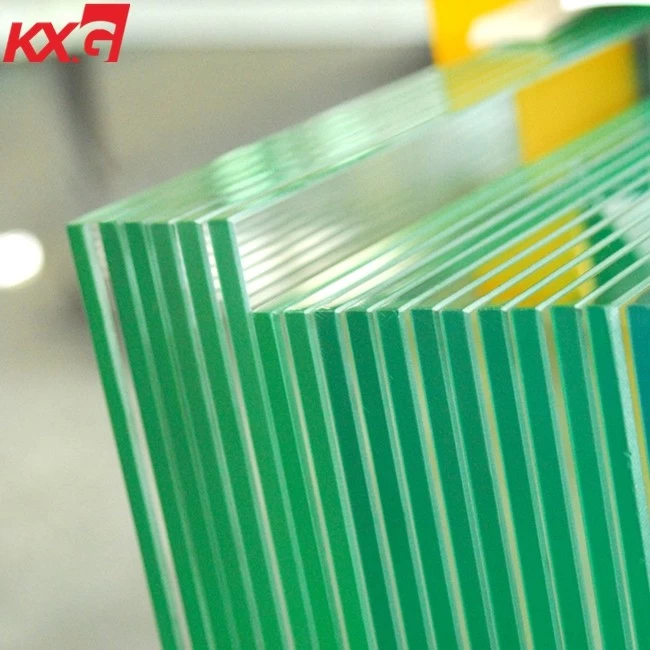

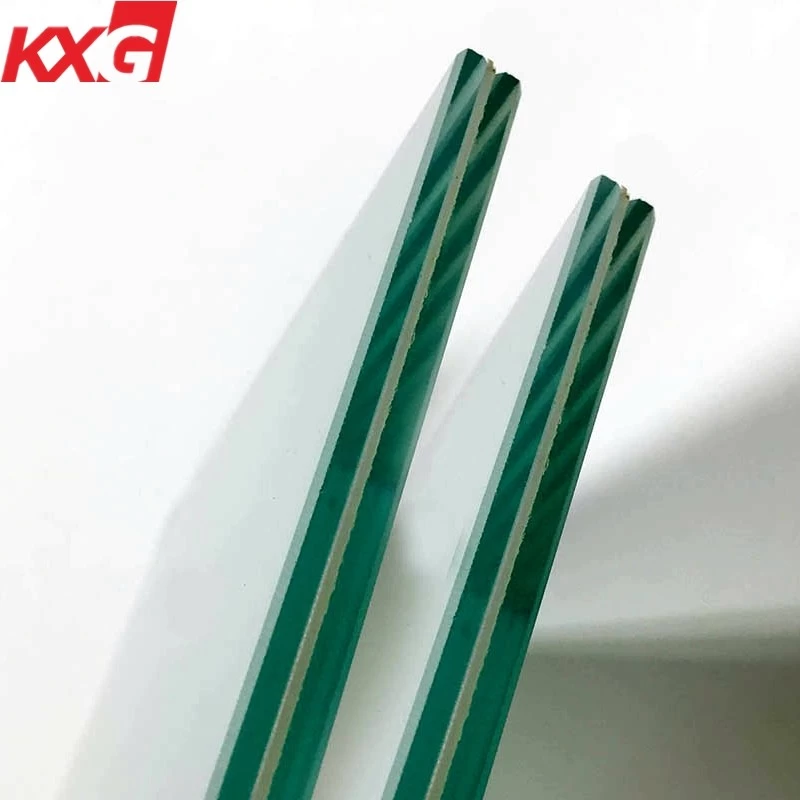

- 1.Product name: Heat soaked toughened safety glass goods

- 2.Color: Custom

- 3.Glass shape: Flat heat soaked tested glass or curved heat soaked tested glass

- 4.Sample: Available(free Sample)

- 5.Glass advantage: Reduce the risk of spontaneous tempered glass breakage

- 6.Application: Window,Door,Partition Wall,Bathroom

- 7.Within 7 to 15 working days production time after the order is confirmed

- 8.Packing: Wooden Crate

Heat soaked test glass suppliers heat soaked toughened safety glass manufacturer

Heat soak test is also called"detonation." Heat soak test is to heat the tempered glass to 280 ° C± 10 ° C, and keep it for a certain time. Promote the rapid completion ofcrystal phase transformation of nickel sulfide in tempered glass, so that itcan be self-explosive after the original use The tempered glass is artificially broken in the hot dip furnace of the factory in advance, thereby reducing theself-explosion of the tempered glass in use after installation. This method generally uses hot air as a heating medium, called "Heat Soak Test",referred to as HST. Widely used for high rise glass facades, overhead glazing, balconies and balustrades.

Heat Soak Test Process

Warming up

The warming phase begins at the ambienttemperature at which all of the glass is located, ending at the time when thelast glass surface temperature reaches 280 °C. Keep the temperature of theglass surface below 320 °C, and try to shorten the time when the glass surfacetemperature exceeds 300 °C.

Keep warm

The holding phase begins at a time when allglass surface temperatures reach 280 ° C and the holding time is at least 2hours. During the entire incubation period, it should be ensured that thetemperature of the glass surface is maintained within the range of 290 °C ± 10°C.

Cool down

When the glass that finally reached 280 ° Cwas finished for 2 hours, the cooling phase was started. At this stage theglass temperature drops to ambient temperature. When the furnace temperaturedrops to 70 ° C, the cooling phase is considered to be terminated. The coolingrate should be controlled to minimize the damage caused by the thermal stressof the glass.

Applications of heat soaked glass

Heat soaked tempered glass, it could makesuperior quality HST toughened laminated glass, HST tempered insulated glass,heat soaked tempered laminated double glazed units, widely used for:

- High rise glass facades

- Glass balustrade, glass balcony railings,glass handrails, glass pool fence

- Overhead glazing, glass roof, glassskylight, etc.

- Any applications where is safetyrequired.

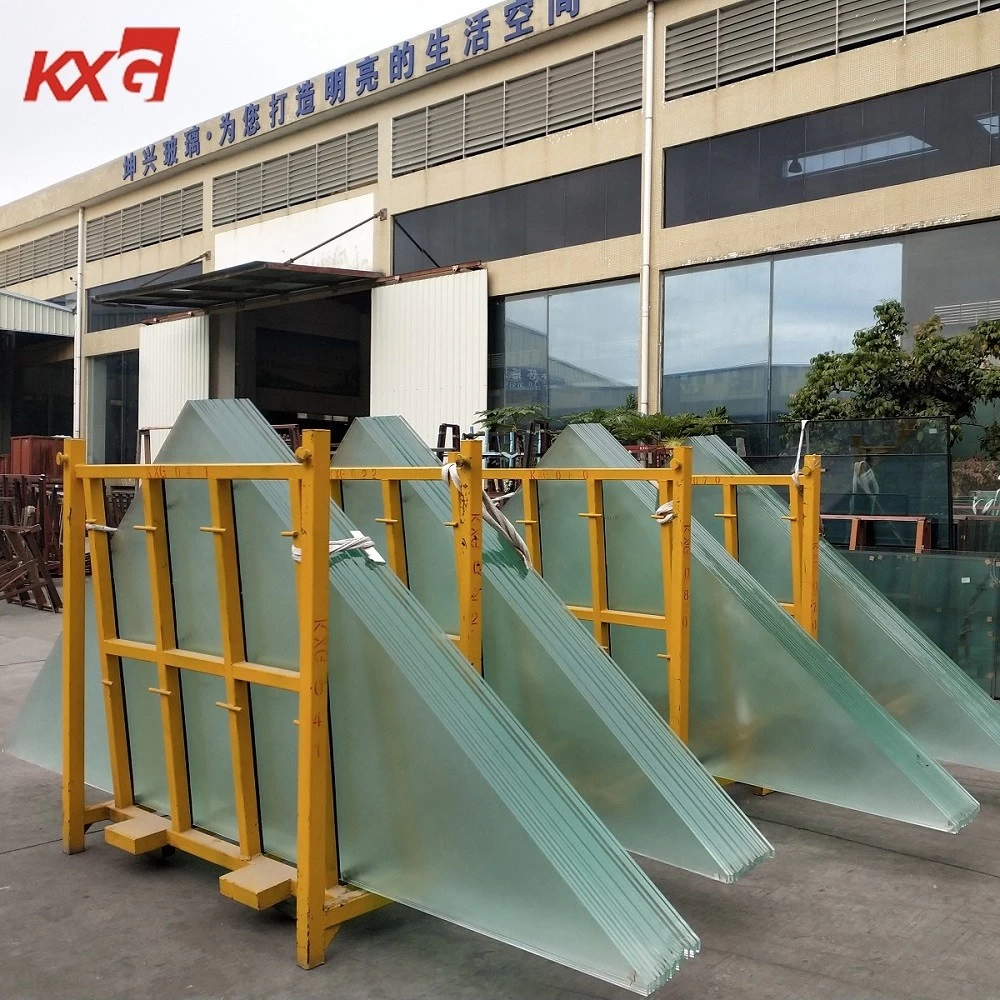

Heat soak test package in Kunxing Glass