- Browse Categories

- Curtain Wall Insulated Glass

- Showerdoor Tempered Glass

- Laminated Tempered Balustrade Glass

- Laminated Insulated Skylight Glass

- Doors and Windows Glass

- Clear Tempered Glass

- PVB SGP Safety Laminated Glass

- Safety Tempered Insulated Glass

- Silkscreen & Digital Printing Glass

- Tempered Curved Glass

- Heat Strengthened Glass

- Acid Etched Frosted Glass

- Heat Soaked Glass

- Colored Tinted Glass

- Heat Reflective Glass

- Table Top Tempered Glass

- Hot Products

-

8.76mm white laminated glass price,8.76mm white translucent laminated glass,obscure laminated glass factory

10mm 12mm 15mm safety toughened glass price,high quality tempered glass factory,safety toughened glass China

Wholesale 8mm 10mm ultra clear silk screen printing tempered glass,digital printing toughened glass price

Factory price decorative frameless curved tempered glass wall for shower,home bathroom glass wall panel

10mm bronze tinted tempered glass factory,10mm thickness bronze toughened glass,10mm bronze tempered glass price

- Certifications

-

- Subscribe

-

Get email updates on new products

Laminated Security Glazing Heat Soaked Test Toughened Laminated Glass Supplier

- 1.Product name:Laminated Security Glazing heat soaked test toughened laminated glass supplier

- 2.Jumbo sizes to 3300x13000mm

- 3.Glass shape: flat heat soaked tested glass or curved heat soaked tested glass

- 4.Color clear, super clear,Ford or dark blue, bronze, green, grey, black, pink, etc

- 5.Advantage: reduce the risk of spontaneous tempered glass breakage.Safety, sound control, UV control, decorative, etc

- 6.Production time within 10 working days after order is confirmed

- 7.Pack in strong plywood crates to avoid breakage

- 8.Application: Window, Door, Partition, Bathroom, Corridor

Laminated Security Glazing Heat Soaked Test 5mm 6mm 8mm 10mm Tempered Laminated Glass Supplier

Heat soak test glass

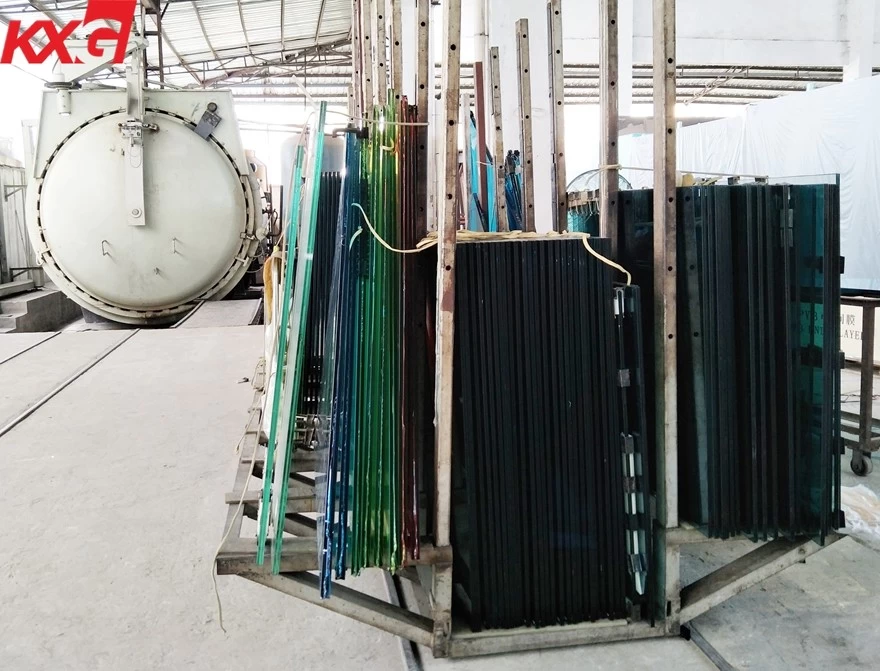

Heat soak test glass is an additional process that is only applied to tempered glass. After tempering, the temperature rises again, the temperature rises to 280 ° C to 300 ° C, and then naturally cools after heating. If there are impurities, bubbles and other defective items on the glass, all of them will bleed, then after Heat soak test, the glass blew. The rate is almost zero. In short, the Heat soak test glassis a change in the environment of the nickel sulfide inclusions, so that the self-explosion can complete the self-explosion, and the tested glass is safe.

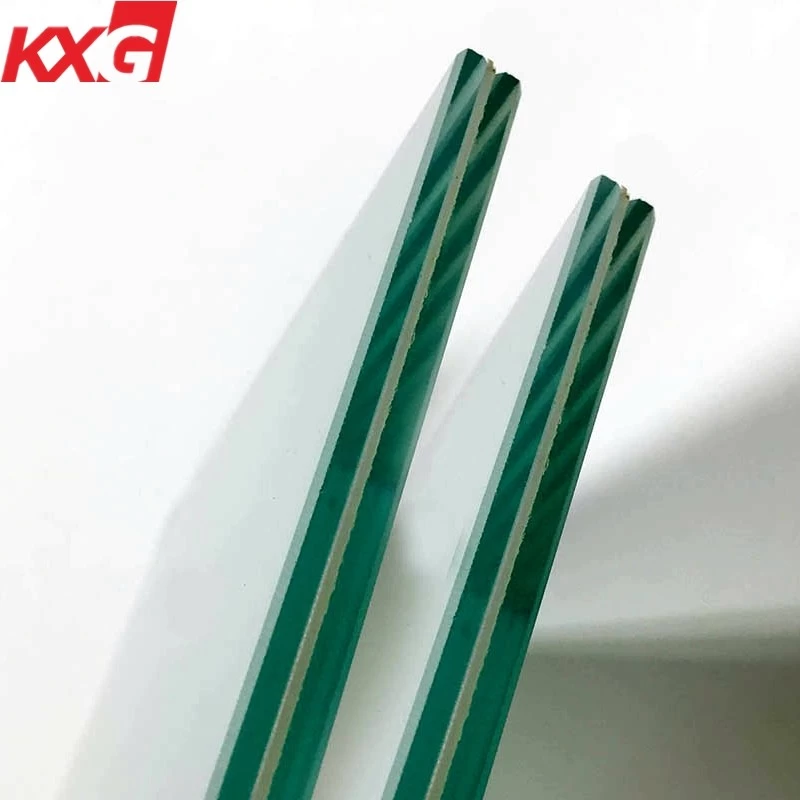

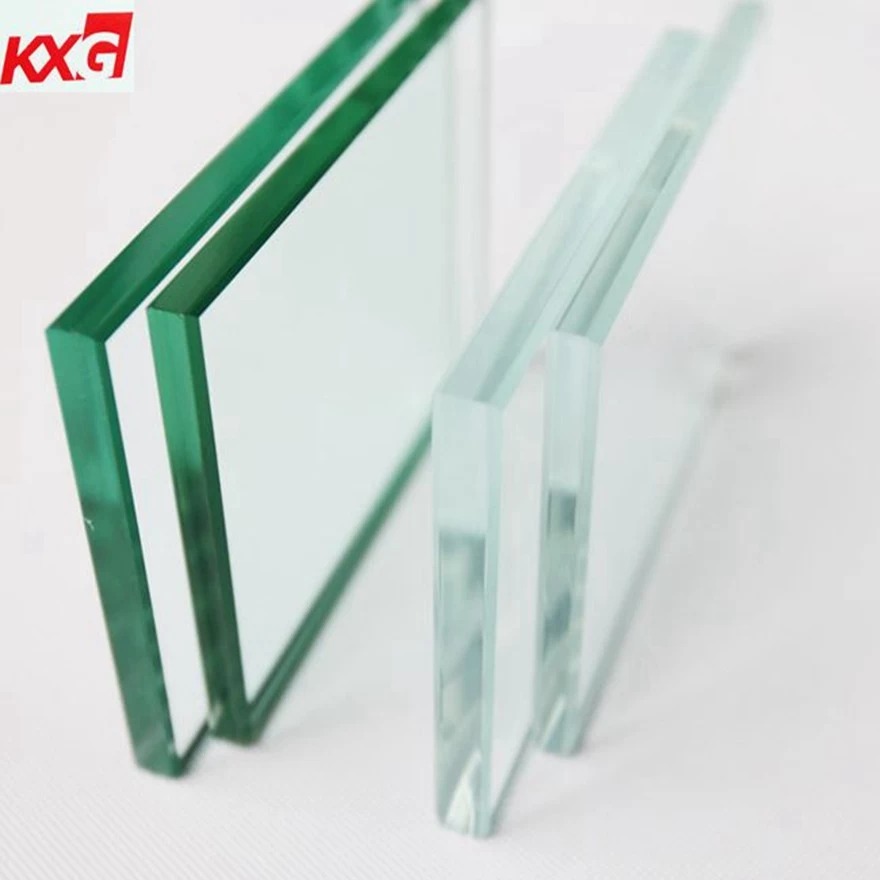

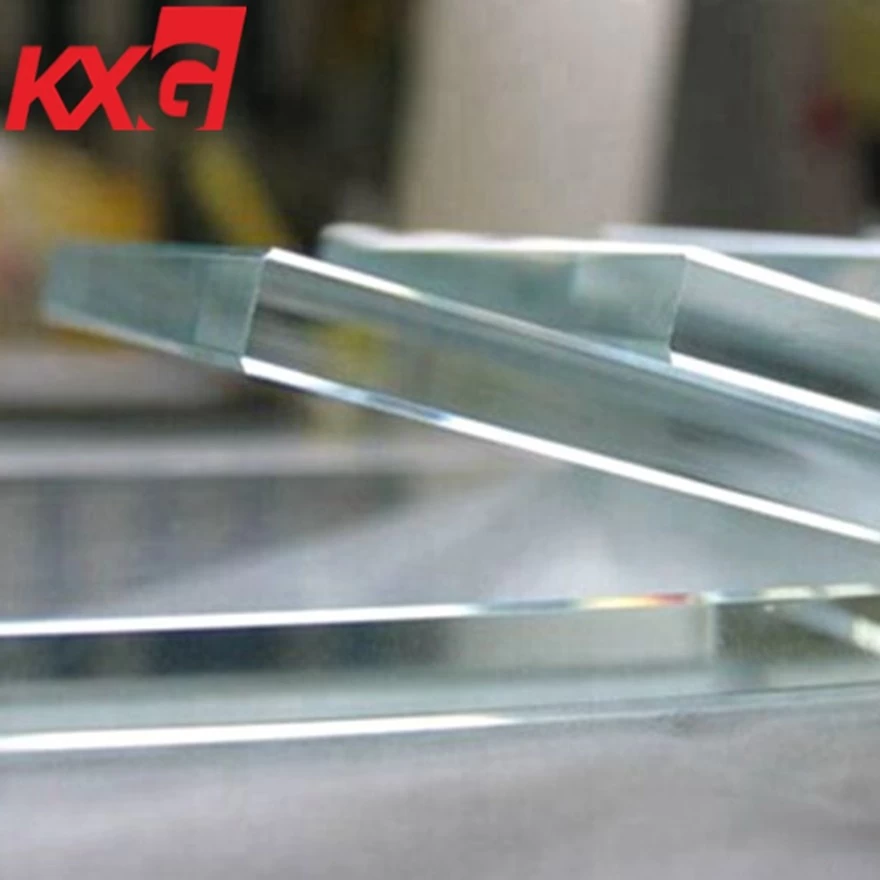

Heat soak testing after tempered glass manufacturing may destroy some defective glass sheets, but this procedure doesnot guarantee 100% elimination of nickel sulfide inclusions. In addition, the Heat soak process may increase cost, cycle time and scrap rate. Heat soak tempered laminated glass, made of two tempered glass by Heat soak test bonding and sandwich of PVB film or SGP film. It can be flat or curved.

Tempered laminated glass and tempered safety glass

The tempered laminated glass is broken safely and may break under the impact of the heavy ball, but the monolithic glass remains intact and the small particles remain adhered to the interlayer film. Tempered glass requires a large impact force to break. Once broken, the entire glass breaks down with numerous fine particles, and only a small amount of broken glass is in the frame.

Features of tempered laminated glass

1. High strength. The impact strength ofthe tempered glass of the same thickness is 4 to 5 times that of the annealed glass, and the bending strength is 4 to 5 times that of the ordinary glass.

2. Safe. When the glass is destroyed by external forces, the debris becomes small, obtuse-shaped particles, similar to honeycombs, reducing damage to the human body.

3. Thermal stability. Tempered glass has good thermal stability, can withstand three times the temperature of ordinary glass, and can withstand a temperature difference of 200 °C.