Analyzing The Mystery Of Tempered Glass Self Explosion

Glass is widely used as the outer layer of buildings due to its uniqueness and irreplaceability. However, the frequent self-explosion incidents have made tempered glass quietly become the focus of public opinion, making people feel scared! In this article, we will unveil the mystery of tempered glass self-explosion and gain an in-depth understanding of its reasons and solutions.

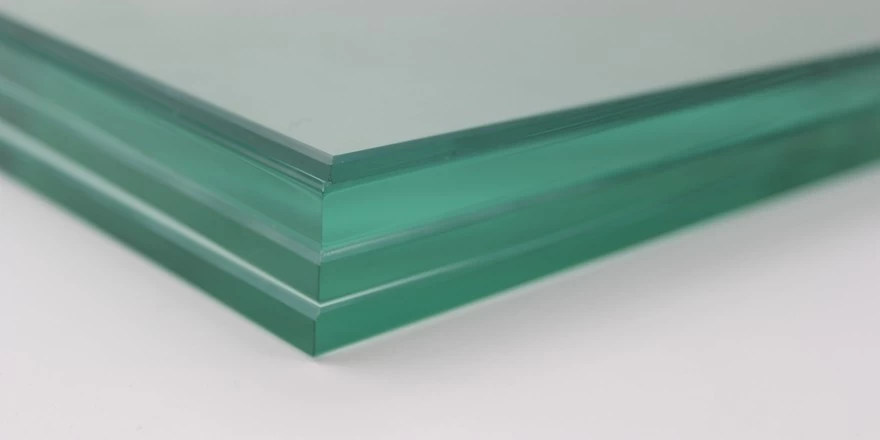

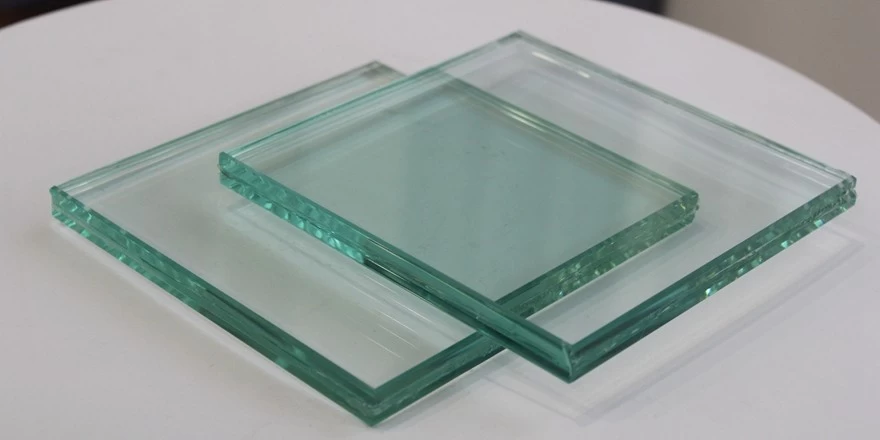

safety tempered 6mm clear glass factory

Definition and identification of glass self-explosion

Tempered glass self-explosion refers to the explosion caused by the tensile stress inside the glass exceeding the tensile limit of the glass without external force.

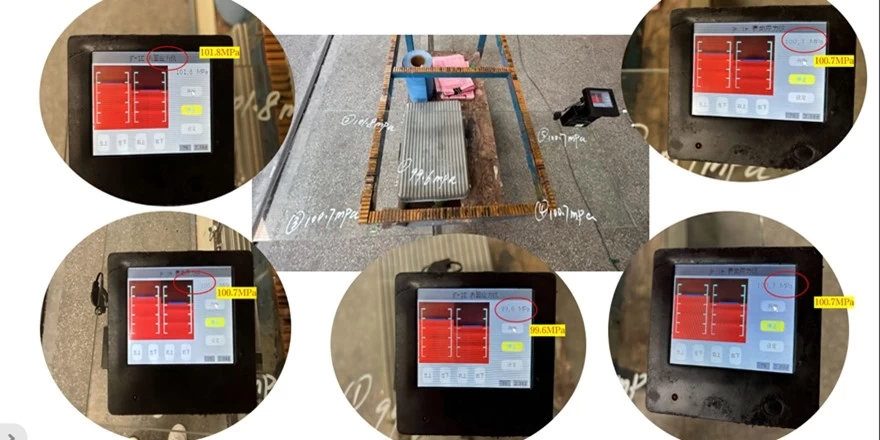

Not all glass breakage is "self-explosion". In the self-explosion broken glass, you can see that the fragments are distributed radially, and there are two pieces of glass fragments shaped like butterfly wings in the center of the radiation, commonly known as "butterfly spots", also known as the number "8" self-explosion point (as shown in the figure below). Tempered glass breakage in other states should be considered non-self-explosion.

The main causes of self-explosion are complex and diverse, mainly including the following aspects:

1. Nickel sulfide inclusions

Nickel sulfide (NiS) inclusions are one of the main causes of self-explosion in tempered glass. In the glass manufacturing process, nickel and sulfur in the raw materials combine at high temperatures to form nickel sulfide. When nickel sulfide crystals undergo phase transformation in tempered glass, their volume expands, causing local stress concentration inside the glass and ultimately leading to self-explosion. According to research, the diameter of nickel sulfide that causes self-explosion is usually between 0.04 and 0.65mm, with an average particle size of 0.2mm.

2. Manufacturing defects

During the manufacturing process of tempered glass, if not properly controlled, some manufacturing defects may be introduced, such as stones, sand particles, bubbles, inclusions, gaps, scratches, and edge bursts inside the glass. These defects will weaken the durability of the glass, increase the risk of self-explosion, and become the trigger for self-explosion.

3. Temperature difference and pressure change

Although tempered glass has high thermal shock resistance, when there is a large temperature difference or external impact force, the internal stress of the glass will be fully readjusted and fluctuate, and local tensile stress may temporarily increase to its bearing limit, which may cause self explosion. For example, the surface of the glass may experience a local temperature increase due to direct sunlight, or the glass may experience excessive local pressure during installation.

4. Improper installation

The installation process of tempered glass is also an important factor affecting its self-exploration risk. Suppose the installation does not comply with the specifications, such as small installation gaps, unreasonable frame design, etc. In that case, it may cause stress concentration in the glass after installation, leading to self-explosion.

KXG prevention plan for tempered glass self-explosion

1. Select high-quality raw materials: select high-quality float glass sheets, use high-grade raw materials for processing, and provide customers with high-quality glass products.

2. You can choose ultra-clear sheets: ultra-clear glass, also known as low-iron glass, has low iron content and few impurities, so the self-explosion rate of ultra-clear glass is also lower.

3. Optimize the tempering process: use advanced tempering equipment and professional processing technology to ensure that the stress can be relatively evenly distributed during the processing process, thereby avoiding uncontrollable self-explosion and improving the overall quality and safety of the product.

4. Use safety configurations: For example, use laminated glass, which is recognized as "absolutely safe" because its fragments stick together after breaking. Laminated glass can be used as a priority to improve safety.

5. Heat-dip treatment: Heat-dip treatment (also known as homogenization treatment) of tempered glass can remove some glass containing nickel sulfide impurities in advance and reduce the risk of self-explosion.

6. Pay attention to installation and maintenance: During the installation process, pay attention to protecting the edges of the glass to avoid edge damage; reserve appropriate gaps to prevent the glass from being subjected to excessive mechanical stress. At the same time, regularly check and maintain the glass and its supporting structure to ensure that they are in good condition.

Detect the broken state of tempered glass

In summary, although the mystery of self explosion of tempered glass is complex, through scientific design, strict material selection, and precise processing measures, we can effectively reduce its self explosion risk and ensure the safety and reliability of buildings.