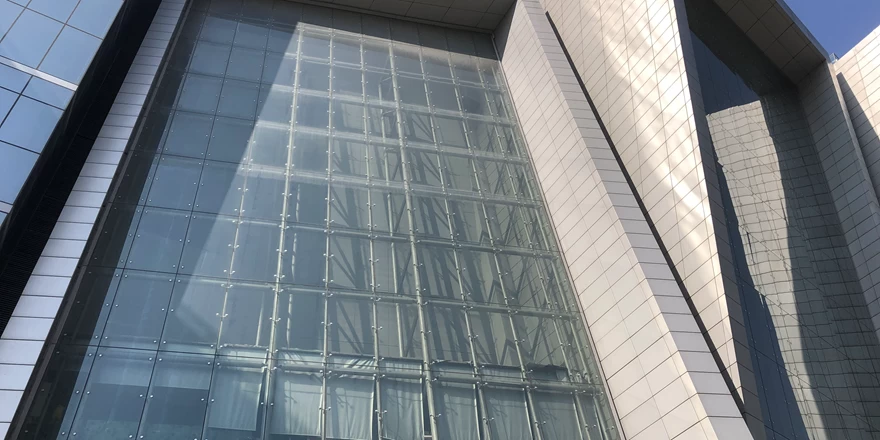

Problems and Solutions of Glass Curtain Walls

With the acceleration of urbanization in China, the number of high-rise buildings is increasing. As an important component of building facades, glass curtain walls enhance buildings' aesthetics and have energy-saving and consumption-reducing functions. With their unique appearance, good lighting effect, and energy-saving performance, architects increasingly favor them. However, with the widespread application of glass curtain walls, problems have gradually emerged, such as poor sealing performance, insufficient wind pressure resistance, glass self-explosion, etc. These problems seriously affect the safety and service life of buildings.

Common problems with existing curtain walls

Poor sealing performance. The sealing performance of glass curtain walls is one of the important indicators for evaluating their energy-saving effect. Structural adhesive and sealant are important sealing materials in glass curtain walls. However, during the use of existing glass curtain walls, due to aging sealing materials, improper construction techniques, and other reasons, the sealing performance has decreased, resulting in problems such as water leakage and air leakage. This not only affects the comfort of the building but also exacerbates its energy consumption.

Building insulated glass curtain wall supplier

Insufficient ability to withstand wind pressure. As the outer surface of a building, the curtain wall directly bears the wind pressure. However, during the design or construction process of existing curtain walls, the influence of wind loads was not fully considered, resulting in deformation, damage, and even detachment of the curtain walls in strong wind weather. This not only affects the aesthetics of the building but also seriously threatens the safety of residents' lives and property.

Glass self-explosion. Glass self-explosion is one of the common safety issues in existing glass curtain walls. Tempered glass may experience self-explosion during use due to uneven internal stress during the manufacturing process. In addition, defects such as scratches and missing corners on the glass surface may also lead to self-explosion. Glass self-explosion not only affects the aesthetics of buildings but may also pose a threat to the safety of residents' lives and property.

Some high-rise building curtain wall glass has experienced self-explosion during use. After testing, it was found that there were impurities of nickel sulfide inside the self-destructing glass, which is one of the main reasons for the self-exploration of tempered glass. In addition, defects such as scratches on the glass surface may also exacerbate the occurrence of self explosion.

Double glazed glass units manufacturer

Improve sealing performance

Choosing high-quality sealing materials: It is crucial to select the type of sealant for insulating glass. Polysulfide adhesive and silicone structural adhesive are commonly used in the market. Silicone structural adhesive has high aging resistance and UV radiation resistance, as well as excellent tensile strength and elongation. Long-term exposure to ultraviolet radiation can cause aging and cracking of polysulfide adhesive, resulting in loss of hollow sealing properties. Its tensile strength and elongation are significantly lower than those of structural adhesive. Relatively speaking, using silicone structural adhesive for insulating glass improves its sealing performance. Select sealing materials with good aging resistance and weather resistance to ensure the sealing performance of the glass curtain wall.

Optimize construction technology: Strengthen quality control during the construction process to ensure the construction quality of injection molding technology, sealing strip installation, and other aspects.

Regular inspection and maintenance: Regularly inspect and maintain the sealing performance of the curtain wall, and replace aging sealing materials and damaged components promptly.

Enhance wind pressure resistance capability

Optimize the design of the curtain wall structure: Reasonably design the curtain wall structure to increase its wind pressure resistance. Such as using reinforced structures and increasing the size of aluminum alloy profiles.

Strengthen connector quality control: Ensure that the quality and installation process of connectors meet regulatory requirements and improve the connection strength between the curtain wall and the building body.

Conduct wind pressure resistance testing and evaluation: Conduct wind pressure resistance testing and evaluation during the curtain wall design and construction process to ensure that the curtain wall system can meet the design requirements.

Reduce the problem of self-explosion of curtain wall glass

Select high-quality glass: Choose high-quality glass raw materials from manufacturers with uniform internal stress and low impurity content to reduce the risk of self-explosion. Alternatively, choose ultra-clear glass raw materials with low iron content and low self-explosion rate.

Strengthen glass surface protection: KXG factory will remove glass with scratches, corners, and edges during the glass processing, providing customers with high-quality architectural glass products. During installation, strengthen surface protection to avoid the occurrence of defects such as scratches.

Choose composite laminated glass or install protective nets: Even if the laminated glass breaks by self-exploration, the glass fragments still stick to the film. Alternatively, safety facilities such as protective nets can be installed on the outside of the curtain wall to prevent glass fragments from splashing around and injuring people after an explosion.

laminated glass curtain wall facade China factory

Heat soak treatment: heat soak treatment the tempered glass, put the glass in the heat oven furnace for high temperature and high pressure treatment, and detonate the glass with uneven internal stress and hidden self-explosion factors in advance.

There are many problems with existing curtain walls during use, such as poor sealing performance, insufficient wind pressure resistance, and glass self-explosion. These issues not only affect the aesthetics and comfort of buildings but also seriously threaten the safety of residents' lives and property. Therefore, it is crucial to adopt effective solutions to common problems with existing curtain walls. By improving sealing performance, enhancing wind pressure resistance, preventing glass self-explosion, and addressing issues such as component aging and damage, the service life of curtain walls can be extended and their safe and reliable operation can be ensured.