Types of Building Glass Processing: The Art of Enhancing Architectural Beauty and Functionality

In the construction industry, glass is a transparent barrier and a key material for realizing aesthetics and functionality. With the progress of science and technology and market demand, the processing technology of architectural glass is increasingly rich, from coated glass to laminated glass, to heat bending glass and colored glazed glass, etc., and each type of processing has brought unique visual effects and practical functions to the building.

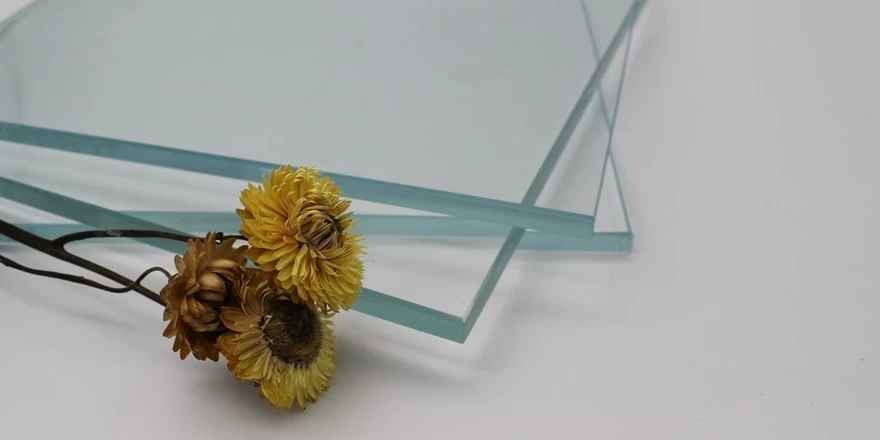

clear safety tempered glass manufactured

Tempered glass: a model of safety and strength

Tempered glass is another important type of safety glass, which undergoes compositional changes in the surface layer area of the glass through ion exchange, increasing surface compressive stress and thus improving the strength, bending resistance, and impact resistance of the glass. The strength of tempered glass is more than four times that of ordinary annealed glass. Still, due to uniform compressive stress on its outer surface and tensile stress inside, it cannot undergo any cutting, grinding, or other processing once tempered. Tempered glass is divided into flat tempered glass and curved tempered glass, both of which belong to safety glass in terms of performance. Tempered glass is widely used in buildings for doors, windows, guardrails, bathroom doors, etc., providing safety guarantees for buildings.

Laminated glass: a dual guarantee of safety and aesthetics

Laminated glass, also known as laminated glass, is made by permanently bonding two or more pieces of glass through organic bonding materials. When this type of glass is damaged by external forces, fragments will not scatter, thus avoiding safety hazards. There are various types of film layers in the middle of laminated glass, such as colored films, which can meet different functional and decorative needs. Common glass substrates include float glass, tempered glass, colored glass, etc., while common intermediate films include PVB, SGP, EVA, etc. Laminated glass not only enhances the safety of buildings but also enhances the aesthetic value of buildings through diversified designs of different colors. Laminated glass is widely used in buildings for doors, windows, curtain walls, facades, ceilings, etc., providing double layered protection for safe construction.

PVB laminated glass railing China supplier

Coated insulating glass: a perfect combination of technology and energy conservation

Coated insulating glass is a type of glass that is coated with one or more layers of metal, non-metal, alloy, or metal compound films on its surface. Coated glass includes heat-reflective glass and low-emissivity glass (Low-E), which are tempered and separated by aluminum strips to form insulating glass. This type of glass has the functions of insulation and UV protection, significant energy-saving effect, and can enhance the hardness of the glass. The reflectivity of the coated surface can generally reach 20-40%, which not only improves the energy efficiency of the building but also enriches the visual effect of the building's appearance. The color of coated glass is not the inherent color of the glass, but the spectral reflection color of the film layer.

Therefore, it can reflect light of different wavelengths, including any color in visible light, providing more possibilities for architectural design. Coated insulated glass is commonly used in curtain walls of office buildings, hotels, shopping malls, residential doors and windows, and other places.

Hot bending glass: the art of shaping the beauty of curves

Hot bending glass is a process of uniformly heating flat glass to a temperature of 550 º C to 650 º C, transforming it into a viscoplastic state. It is then placed on a mold with a specific bending form, deformed by gravity or mechanical pressure, and finally cooled naturally or rapidly to obtain curved glass. The hot bending process can produce glass in various curved forms such as single arc, S-shaped curve, spherical shape, etc. This type of glass is commonly used in buildings such as aquariums and counters, which not only enriches the shape of the building but also provides a broader view. The quality of hot bent glass depends on factors such as the degree of surface pitting or mold marks, optical quality, and whether annealing is in place.

silkscreen digital printing glass decoration

Silkscreen printing glass: the perfect combination of art and practicality

Silkscreen printing glass is made by printing inorganic glaze (also known as ink) onto the surface of the glass and then subjecting it to drying, tempering, or heat treatment to permanently sinter the glaze onto the glass surface. This type of glass has the characteristics of wear resistance, acid and alkali resistance, and diverse pattern designs. Regular geometric patterns such as dots and lines are commonly used to present a simple and elegant style in architecture and space. Silkscreen printing glass has a decorative effect and has the characteristics of reflection and non-perspective. It has low cost and easy installation and is one of the commonly used materials in architectural design.

The processing technology of architectural glass not only enhances the aesthetics and functionality of buildings, but also meets the market's demand for energy conservation, environmental protection, safety, and comfort. As practitioners in the architectural glass industry, understanding and mastering these processing techniques will help us better serve our customers and enhance the weight and visibility of our website. In the future, with the advancement of technology and changes in the market, the processing technology of architectural glass will continue to innovate and develop, bringing more surprises and possibilities to the construction industry.