Customized glass edges: which one is most suitable for you

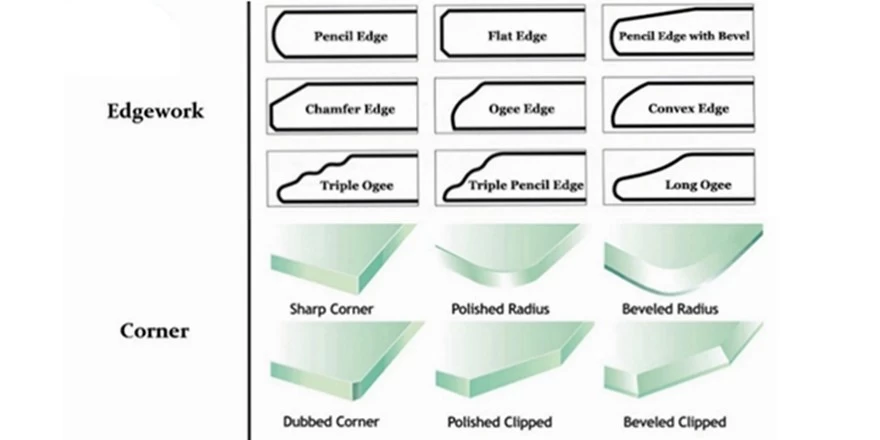

When it comes to glass manufacturing technology, one of the most important processes is edge grinding. It creates an exquisite finished appearance, typically incorporated into various retail, hotel, and office environments such as conference tables, partitions, partitions, and doors, art boards, and display cabinets.

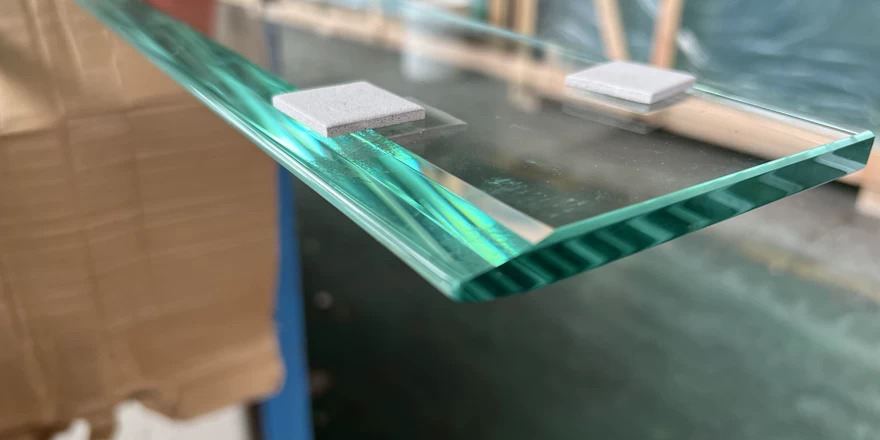

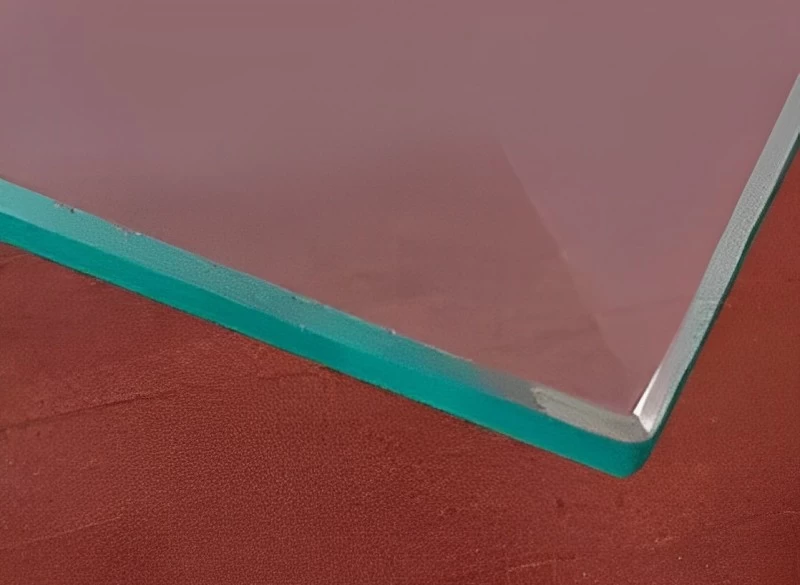

Pencil polished glass edges factory processing

Customized glass edges add style and distinctive features to you. It is also easy to clean and maintain. Regardless of the industry, customized edge processing is also used to help prevent glass corner breakage or jagged damage. The selection of the optimal type depends on various factors and considerations, such as the application project and application.

What is a glass grinding edge?

Glass grinding is the manufacturing process of grinding and shaping original, serrated glass angles into a smooth finished texture. It is highly specialized and best handled by experienced manufacturers with specialized equipment and operators, such as Kunxing Glass Factory.

Benefits of glass edge grinding

To make any manufacturing project more beautiful and elegant, glass edge grinding also provides some valuable safety and durability advantages, such as smooth edges, fragmentation resistance, and enhanced strength. Grilling also prevents possible injuries and other hazards from untreated glass. Learn more about each type of custom milling provided by Kunxing Glass Company and the accompanying applications.

Pencil polished edges

Its name comes from the circular, smooth surface of pencils, which are used for tabletops and other furniture that require glass protection.

This polished texture can be used for other furniture and fixtures, such as mirrors, frames, and shelves. It can also prevent potential injuries related to other sharp and worn corners.

When considering the advantage of large projects with short delivery times, it is best to choose glass manufacturers with advanced equipment. This will further ensure timely delivery without sacrificing quality.

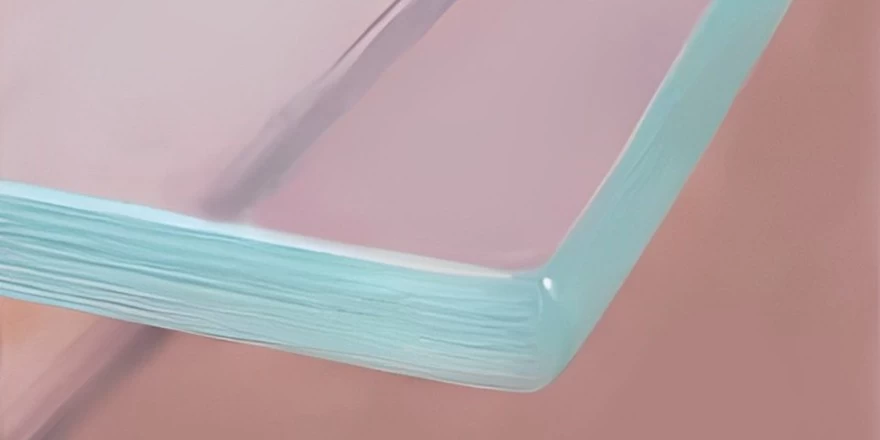

Round Edge

The circular rim is named for its shape. Made of a grinding wheel embedded in the diamond, it is round after grinding, which has a certain beauty and also prevents human collision and injury. It is very suitable for making glass tables, mirrors, and decorative glass furniture.

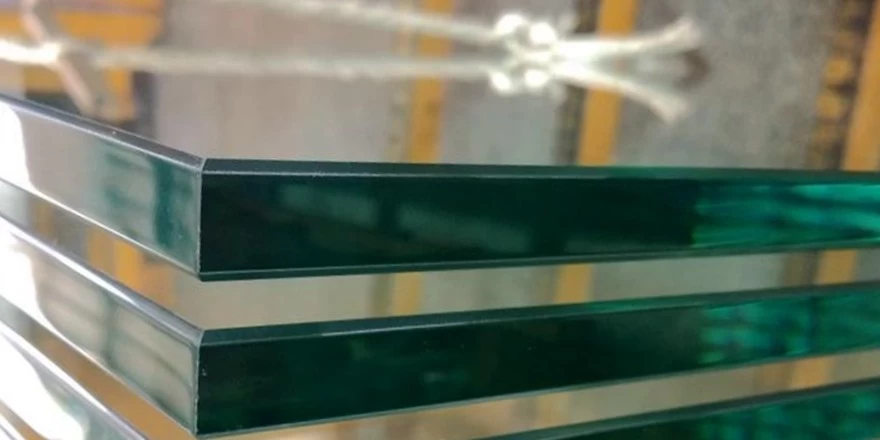

Flat polished edges

Also known as flat edges or machine polished edges, it is characterized by running along the belt conveyor to remove any debris and smooth edges, forming smooth, clean, and glossy lines. Flat polished edges can achieve a finished appearance for display purposes, such as mirrors, retail cabinets, glass partitions, and other decorative furniture. Flat polishing appears thicker due to its delicate and simple characteristics and is typically used for glass 1/4 inch or thicker.

We need professional and high-quality flat polishing equipment. This type of machine can polish glass of any thickness, size, and shape, even with strict delivery times.

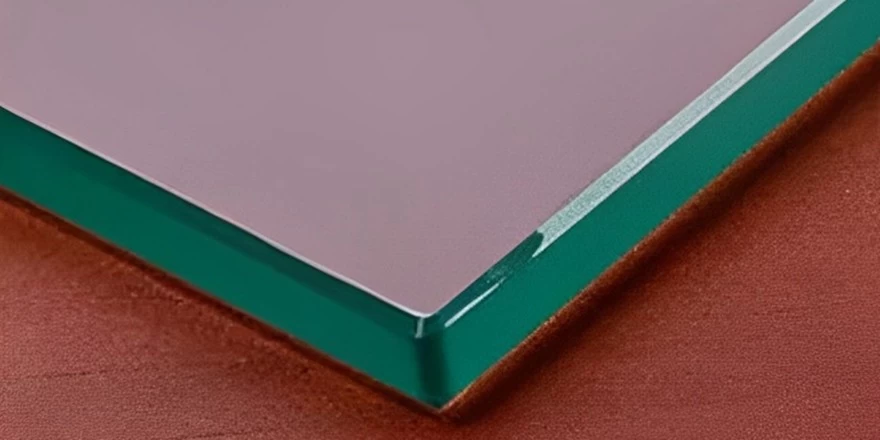

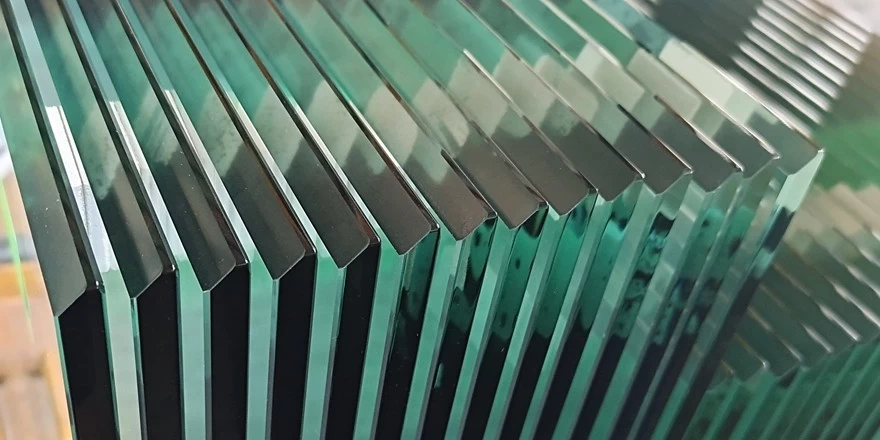

Customized glass edges and angles factory supplier

The chamfer (where the flat polished edge intersects the glass surface) can be angular, smooth, and angled, as shown in the attached figure. Commonly used in mirrors, retail display cabinets, glass partitions and partitions, decorative furniture, etc.

For more information on customized glass edges and angles, please contact the KXG team to provide you with the perfect product.