High quality insulated glass is produced in this way

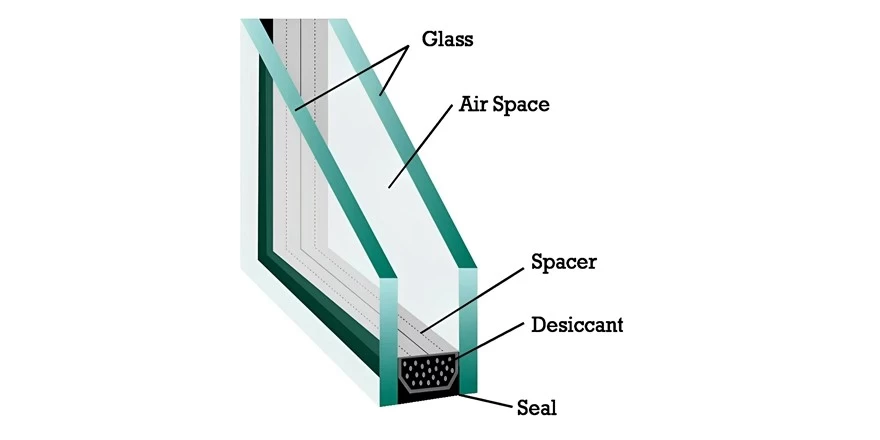

Since the use of insulating glass, its production has gone through processes such as double glazing, simple double glazing, manual single-pass sealing, double-pass sealing, and the composite strip-type insulating glass that has appeared in recent years. How to make high-quality insulating glass?

Insulated glass factory supplier

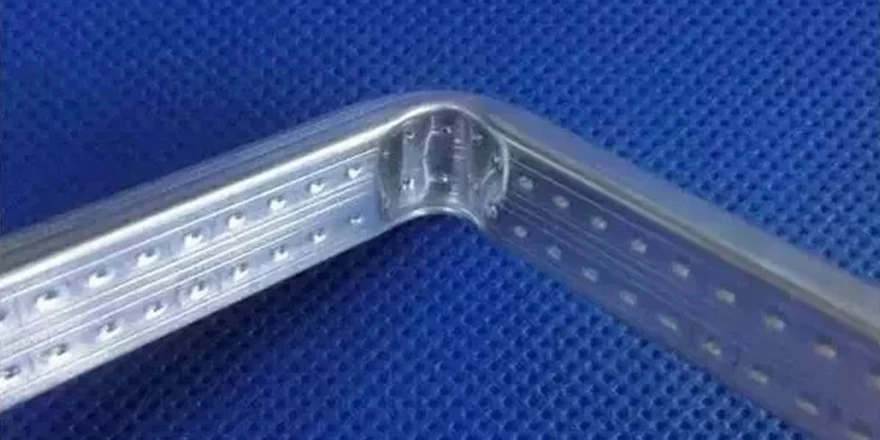

1. Insert angle joint

The grooved aluminum type insulating glass commonly used by KXG requires double sealing. No matter which sealing problem occurs, the sealing failure of the insulating glass will eventually occur. The inner channel is sealed with butyl rubber. Current domestic and foreign mechanical processes cannot guarantee effective sealing of the gusseted joints.

First of all, we must establish a premise that no matter which sealing problem occurs, it will eventually lead to the failure of the insulating glass seal; then we will evaluate this process of manually filling the outside of the aluminum strip angle with butyl glue: in advanced production technology Outdated manual work.

Moreover, if you go to the workshop and observe, you will find that almost every gusseted joint is not filled with enough butyl glue - that is, most of the gusseted joints are still single-pass sealed, which will directly lead to the sealing of the insulating glass. Invalid. The production department must pay attention to this link, but why are most of them still dissatisfied? First, workers basically receive basic wages plus piece wages. Omitting this link can save more time; second, this process operation is relatively cumbersome and the appearance of whether to do something or not or to do more or less cannot be observed from the outside.

The bent aluminum lattice bars are continuously bent at the four corners, and the sealing of the angled joints is basically the same as that of the straight lines. The weakest part is in the push-in connection.

The above reminds us: Pay attention to the sealing of the gusset joints and fill them adequately.

2. Adsorption time of molecular sieve

Even if all the insulating glass materials are of the best quality, it is possible that the insulating product will still fail to pass the inspection. Each material has its own characteristics, such as molecular sieves.

The saturated adsorption time for the divided sieve test is 24 hours. No matter how good the production process is, we have a basic exposure time requirement for the use of molecular sieves: from the time the bag is opened until the second sealant of the insulating glass is filled, the time cannot exceed 4 hours. If there are higher requirements for insulating glass, the exposure time can be shortened to 1.5 hours. The shorter the exposure time, the better, but a production process of less than 1.5 hours is difficult to operate in mass production.

3. Curing time of polysulfide rubber

General operations are between 3-6 hours. As we all know, the curing time can be adjusted by the ratio of components A and B.

This involves two issues: First, the curing time cannot be adjusted arbitrarily. If the curing time is too long, there may not be enough space in the workshop; if it is too short, the curing speed will be too fast and there will not be enough time for coating. More seriously, the cured polysulfide will be damaged. The performance of the glue is reduced, and the specific time should be within the range given by the manufacturer.

Second, we can judge part of the quality of polysulfide rubber - construction performance. For example, Zhongyuan polysulfide rubber has a ratio of A and B components of 100:7~100:14, while many manufacturers give a ratio of 10:1. As you know, this is only a theoretical value. In practice, It is impossible to achieve in operation, which has also become an excuse for some manufacturers to be irresponsible for quality.

4、 Drying rate of insulating glass and water mist of new products

Some newly produced insulating glass was placed under the scorching sun, and soon water mist appeared, causing everyone to be surprised and suspicious of the quality and manufacturing process of the insulating glass material.

High quality insulating glass wholesale

This phenomenon can be explained by the drying rate of insulating glass. As we all know, molecular sieves adsorb water vapor through a process. The better the molecular sieve, the slower the adsorption speed. The molecular sieve only partially adsorbs, and the static air inside the hollow glass still contains a lot of water vapor, resulting in water mist phenomenon. Wait for the molecular sieve to complete the task, and the water mist will naturally disappear.

Several factors that affect the drying speed of insulating glass include: air humidity in the production workshop, filling ratio of molecular sieves, adsorption speed of molecular sieves, size and density of aluminum strip pores, sealing quality, etc.

Choose high-quality hollow products and come and contact us.