How to choose the appearance color of Low-emissivity glass?

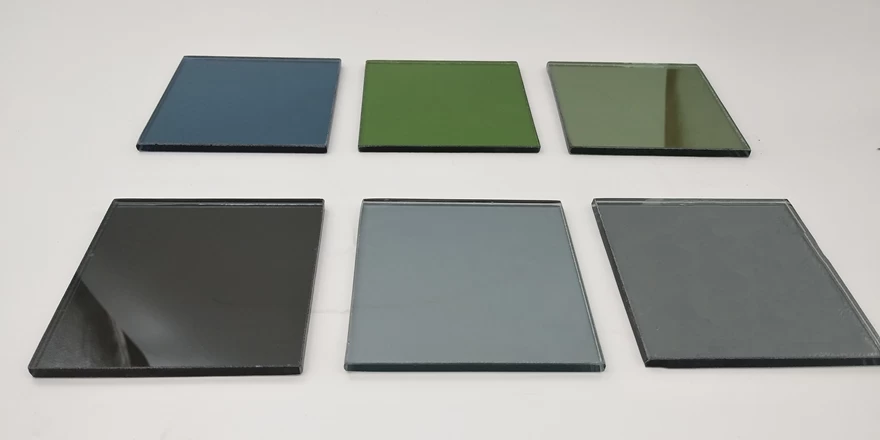

LOW-E glass, also known as low-emissivity glass, is a kind of energy-saving glass. Due to its superior energy-saving performance and rich and colorful colors, it has become a beautiful landscape in public buildings and high-end residences. Common LOW-E glass colors include blue, gray, colorless, etc. These mainstream colors are durable and are the mainstream exterior colors of urban buildings.

Low e glass windows door supplier

We use glass as a curtain wall for the following reasons: adopting natural light, reducing energy consumption, and being aesthetically pleasing. So how do we choose the right color? We will explore the following aspects: transmittance, outdoor reflection color, film surface reflection color, transmittance color, and the influence of the original glass and structure.

1. Appropriate light transmittance

There are certain regulations on the light transmittance of exterior glass used in public energy-saving buildings, and the shading coefficient and light transmittance are closely related. When we choose glass, we need to refer to the specific performance parameters. It can also be based on the building use (such as residential buildings requiring better lighting), the owner's preferences, local solar radiation illumination factors, other relevant national and local energy-saving standards, etc.

2. Suitable for outdoor colors

Appropriate outdoor reflectivity:

Outdoor reflectivity is a color factor that is easily overlooked. In fact, not only the specific red, green, yellow, blue, and other color values, but the reflectivity of glass is also closely related to its color expression.

The outdoor reflectivity of hollow LOW-E glass is generally between 10% -30% (according to national regulations, the external reflectivity of LOW-E glass should not exceed 30%).

① 10% -15% reflectivity: It can be called low reflection. The color of the glass with low reflection is less irritating to the human eye, and is not very dark, which does not give people very distinct color characteristics;

② 15% -25% reflectivity: It can be called medium reflection. Glass with medium reflection has the best color expression and is easy to highlight the color of the film layer. For example, blue glass has a reflectivity in this range, and the color will be very bright blue. Similarly, other colors will also be the same;

③ 25% -30% reflectivity: It can be called high reflectivity. Glass with high reflectivity has a strong reflectivity, which is highly irritating to the human pupil. The pupil will adaptively shrink to reduce the amount of light incident. Glass with high reflectivity can cause certain light pollution and safety hazards under certain conditions.

3. Suitable color values:

Color is like the coat of a building. We need to choose the right color based on the customer's preferences and usage functions. Featured project color recommendations:

Traditional banking, financial, and high-end consumer places need to create a sense of grandeur. At this time, if you choose gold-colored glass with pure color and high reflectivity, you can create a good atmosphere.

For projects such as libraries and exhibition halls, you can choose high-transmittance and low-reflection colorless glass, which has no visual obstruction or sense of restraint and can provide a relaxed and comfortable reading environment.

Reflective color glass insulated glass curtain wall factory

Memorial public construction projects such as museums and martyrs’ cemeteries need to give people a solemn and heavy feeling. We can choose medium-transparent and medium-reflective gray glass.

For general residential projects, in order to take into account safety, lighting, comfort, and other aspects, you can choose medium-high transparent colorless, blue-gray, gray, and other color glass.

4. The influence of transmission color and film surface color

Generally speaking, we pay more attention to outdoor reflective colors and less attention to transparent colors and off-film reverse colors.

The film surface of LOW-E glass is facing indoors. If we look at the glass indoors, it is difficult to see the reflection color of the film surface due to the intensity and angle of light. Generally, what we see is through color. If we turn on the light indoors in the dark at night and at a specific angle, we can see the film's surface color more clearly.

In the national standard, only the color difference range of the outdoor reflection color of the glass is specified, and there are no specific restrictions on the transmittance color and film surface color.

5. The influence of different original glass and glass structures on color

Sometimes, when choosing a color, we select the color of a certain LOW-E glass with a regular configuration of 6+12A+6. If the original piece and structure have changed, the color and sample selection of the glass may be found after it is installed on the wall. There is a big difference from time to time for the following reasons:

1) Ultra clear glass: Because the impurity iron ions in the glass have been removed, the color will not appear green. The color of conventional hollow LOW-E glass is adjusted based on ordinary white glass. If the film is coated on the ultra-clear substrate, Certain colors may have a certain degree of redness, and the thicker the glass, the greater the color difference between normal clear and ultra-clear.

2) Thick glass: The principle is the same as above. The thicker the glass, the greener the glass appears. The thickness of the single piece of insulating glass increases, and the use of laminated insulating glass makes the color greener.

3) Tinted glass: Common tinted glass include green wave, gray glass, bronze glass, etc. Since these original pieces have a very heavy color, the color of the original piece after coating will cover up the color of the coating layer. The role of the membrane layer is mainly in the thermal properties.

Therefore, when selecting LOW-E glass, we must not only consider the color of the standard structure but also consider the factors of the glass substrate and structure.

Before large batches of LOW-E glass are put on the wall, it is a necessary process to put small batches of color on the wall. However, when comparing colors outdoors, there will be more interference items, such as the intensity of the sunlight on the day and the angle of the sunlight, color contrast between different LOW-E glass, etc. We can observe the first two items through different time periods and different angles, but the color contrast between different colors of glass sometimes causes us trouble.

If we cannot eliminate the influence of interfering colors in time during the color-matching process, we may select the wrong color and regret it when the products are put on the wall in large quantities.

Please feel free to contact us if you need anything.