Is the self-explosion of tempered glass caused by high temperature in summer

Tempered glass is a safety glass recognized by regulations and is widely used in places with high requirements for mechanical strength and safety, such as glass doors, architectural curtain walls, facade windows, interior partitions, furniture, partitions near heat sources, and places subject to severe cold and heat shocks partition.

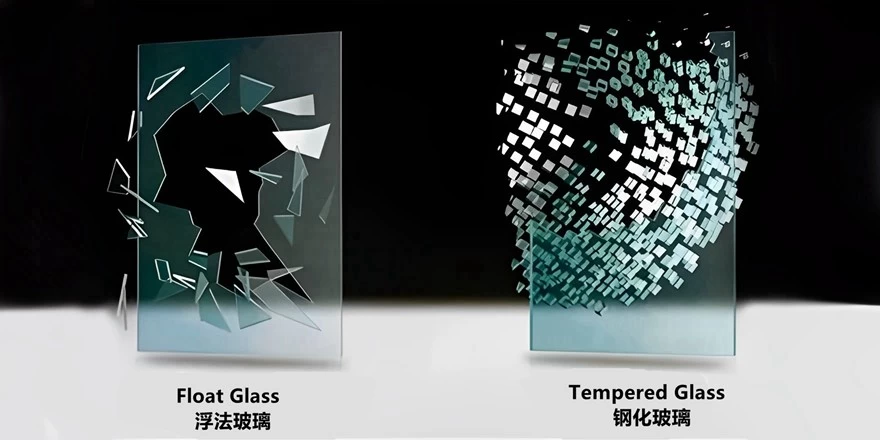

The characteristics of tempered glass determine that self-explosion is unavoidable, and the time and conditions of self-explosion cannot be predicted. Therefore, in order to prevent the harm caused by tempered glass self-explosion, some measures or methods are often taken during glass processing and installation. To reduce the loss caused by the self-explosion of tempered glass.

Factors affecting the bursting of tempered glass:

1. Glass damage factors: The glass surface and edge are not careful in handling, installation, and maintenance, resulting in an explosion, surface corrosion, edge chipping, etc., which are easy to destroy the stress of the tempered glass and cause the self-explosion of the tempered glass.

2. Installation factors: During the installation process, if the installation gap is small or the glass is in direct contact with the frame, under the sunlight, the expansion coefficients of the glass and the frame are different, which will easily cause the glass edge or corner extrusion pressure, causing the tempered glass to burst.

3. Glass processing factors: drilling or cutting corners of the tempered glass is easy to burst.

4. Natural factors: strong typhoons and other wind disasters lead to the failure of the wind pressure design, which can cause the tempered glass to burst.

How to reduce the chance of self-explosion of tempered glass?

1. Segment and use large-size glass to avoid excessive glass tempering stress.

2. Use the float glass containing fewer nickel sulfide stones, that is, use high-quality float glass.

3. Secondary heat treatment of tempered glass, usually called heat soak treatment. Effectively reduce the self-explosion rate of tempered glass after factory installation.

4. Put a high-performance polyester film on the glass. Polyester film is commonly known as safety explosion-proof film, when the glass is broken for various reasons, it can stick to the glass debris to prevent splashing, protect the personnel inside and outside the building from the splash of glass debris, wind and rain and other external objects are difficult to cause damage to the indoor.