The difference between heat strengthened glass and toughened glass

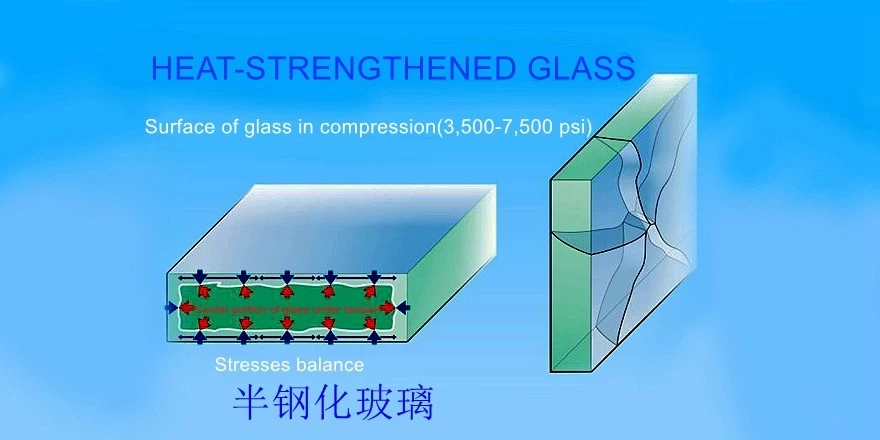

The processing principle of heat strengthened glass is similar to that of physically toughened glass, and the difference between the glass is not visible on the surface. The heating temperature is about 650 ℃, the toughened glass cools quickly, the heat strengthened glass cools more slowly, making the heat strengthened glass strength between toughened glass and ordinary glass.

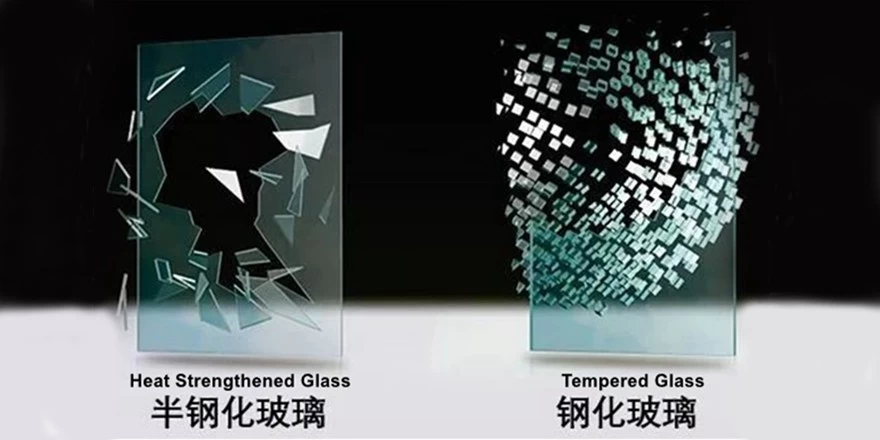

However, the crack of heat strengthened glass rupture extends from the point of initiation to the side, similar to annealed glass, the fragments are larger, so heat strengthened glass does not belong to the safety glass, heat strengthened glass has the advantage of better flatness than toughened glass, while its thermal stability and strength is also better than annealed glass.

The special stress structure of heat strengthened glass allows the fragments to remain in the frame when it is damaged, unlike toughened glass that falls off completely in granular form when broken, gaining time for glass replacement. You can choose to install heat strengthened glass in scenarios where you want the glass not to shatter completely in the event of an accident and where personal safety is not involved. Or use the flatness of the heat strengthened glass, the use of laminated process processing, so that two pieces of heat strengthened glass into safety glass, its flatness and stack difference will be much better than the tempered laminated glass.

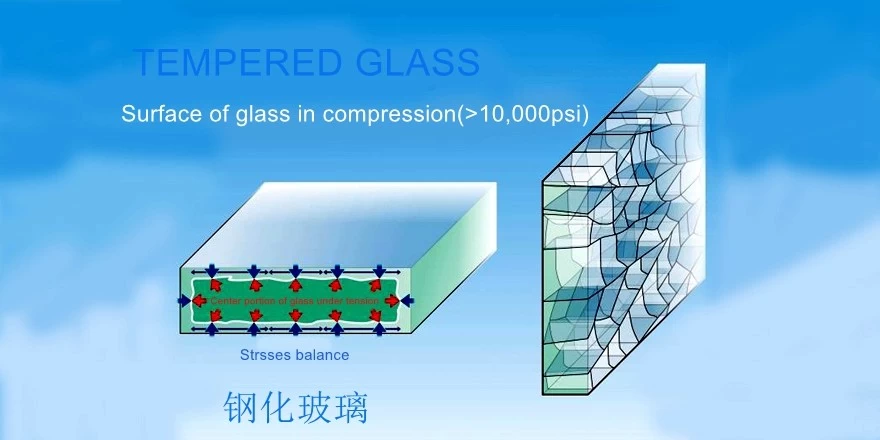

The surface stress of heat strengthened glass is: 24-69mpa, while the surface stress of toughened glass is above 90mpa.

What are the characteristics of tempered and semi toughened glass?

1.Toughened glass

Safety: Broken in small blunt particles, will not cause great harm to the human body.

High strength: Generally 4 times and more than the strength of ordinary glass.

Deflection: 3-4 times greater than ordinary glass.

Thermal stability: Toughened glass has good thermal stability. Toughened glass withstands 2.5-3 times the temperature difference of annealed glass (up to 200°c). It can meet the environmental cold and heat changes considered in the building, indoor and outdoor shading of sunlight, thermal shock of heating or air conditioning, etc.

The biggest disadvantage of toughened glass is that it is easy to self-explode, and the larger the toughened glass area corresponding to the higher the risk of self-exploding.

So how to deal with the danger of self-explosion of toughened glass? The first is to make heat soak test (that is, heat soaking treatment),put the toughened glass into a hot soaking furnace to treat the equipment with high temperature and high pressure, and detonate due to uneven internal stress and potential self-explosion factors of the toughened glass. Reduce the self-explosion rate of toughened glass.

2. Heat strengthened glass

Safety: It does not meet the standard of safety glass and does not belong to safety glass.

Strength: Generally 2 times or more than that of ordinary glass.

Thermal stability: The thermal stability of heat strengthened glass is better than ordinary glass.

Heat strengthened glass has a low self-explosion rate, but the biggest regret is that it cannot be used as safety glass. If you want to choose heat strengthened glass, you can only do lamination process on it to make it into safety glass.