What is the difference between PVB and EVA film used in laminated glass?

The intermediate film used for laminated glass is generally PVB and EVA. Today, let's see what is the difference between these two films.

1. PVB is short for polyvinyl butyral; EVA is short for ethylene-vinyl acetate copolymer.

2. Processing and storage conditions: PVB needs to be processed and stored under low temperature (18-22 ° C) drying (humidity 25% - 40%). In particular, the requirements for humidity are very strict, and the high temperature (120-140 ° C) high pressure (1.0-1.5 MPa) is used for the splicing, and most of them are produced by autoclave; EVA processing and storage conditions are relatively low, the temperature does not exceed 30 ° C, the humidity is less than 80%, the equipment requirements for the splicing are also low, the vacuum degree ≥ 700mmHg (0.092Mpa), the temperature is 100-110 ° C; The PVB splicing process is more complicated than EVA, and it takes longer and consumes more energy.

3. Characteristics: PVB's aging resistance is stronger than EVA, and impact resistance PVB is also stronger than EVA.

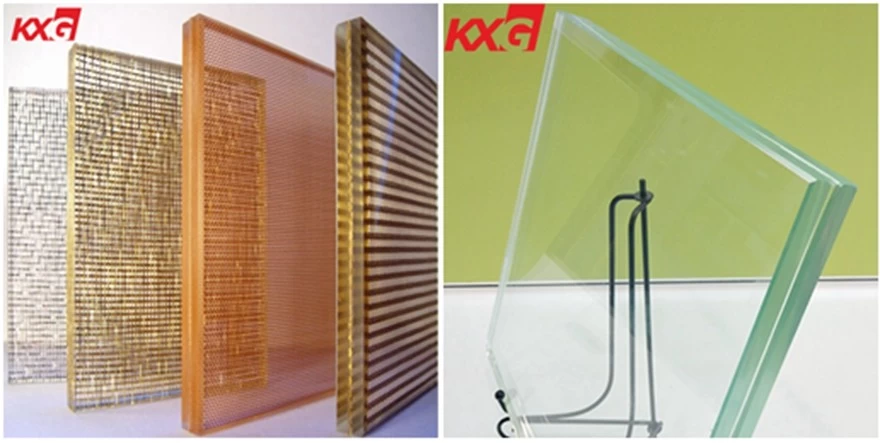

4. Uses: PVB is often used outdoors, such as building curtain walls, doors and windows, etc. EVA is more used for interior decoration glass. The film used in the middle of the fabric laminated glass is EVA