Five characteristics of PVB laminated glass

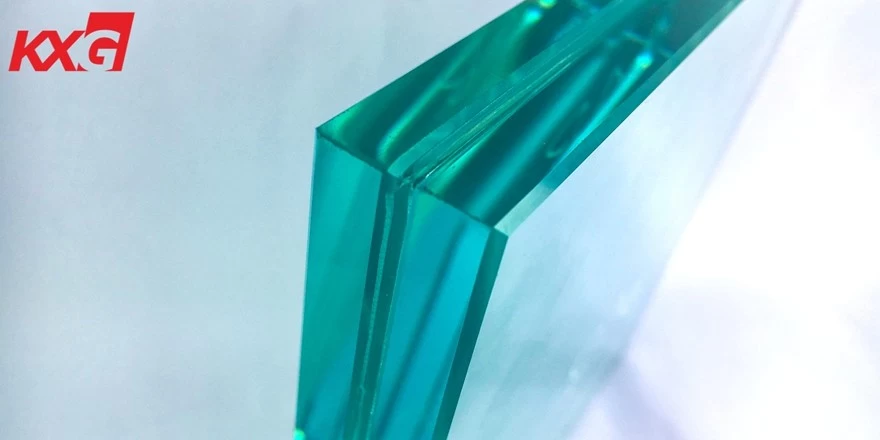

Laminated glass is two or more pieces of glass sandwiched with an intermediate film,which is compressed by a hot press to exhaust the intermediate air as much as possible,and then placed in a high-pressure steam kettle to use high temperature and high pressure to dissolve a small amount of residual air into the middle film.At present,polyvinyl butyral (PVB) is widely used as intermediate film for laminated glass curtain wall.

It is suitable for regular float laminated glass, flat tempered and half-toughened laminated glass, curved tempered or half-toughened laminated glass and hot-bent laminated glass.

Five characteristics of PVB laminated glass

I. Security

When subjected to an external impact, the elastic intermediate layer can absorb the impact and prevent the impact object from penetrating.

II. Anti-theft

PVB laminated glass is very tough, even if thieves crack the glass, because the interlayer is firmly adhered to the glass, it still maintains its integrity, making it impossible for thieves to enter the room.

III. Sound insulation

Since PVB film has the function of damping sound waves, PVB laminated glass can effectively suppress the transmission of noise, and its sound insulation effect is very obvious.

IV. Anti-ultraviolet performance

PVB film can absorb more than 99% of ultraviolet rays, thus protecting indoor furniture, plastic products, textiles, carpets, artworks, ancient artifacts or commodities from fading and aging caused by ultraviolet radiation.

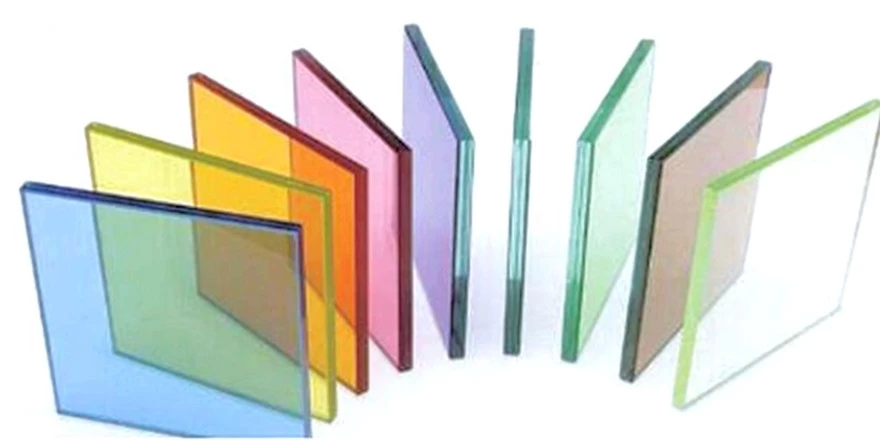

V. Energy saving

Architectural laminated glass made of PVB film is effective in reducing solar transmission. Laminated glass made with dark, low-transmittance PVB films of the same thickness has a greater ability to block heat. At present, domestically produced laminated glass has a variety of colors.