Some points that have to be mentioned when using LOW-E glass for curtain walls and doors and windows

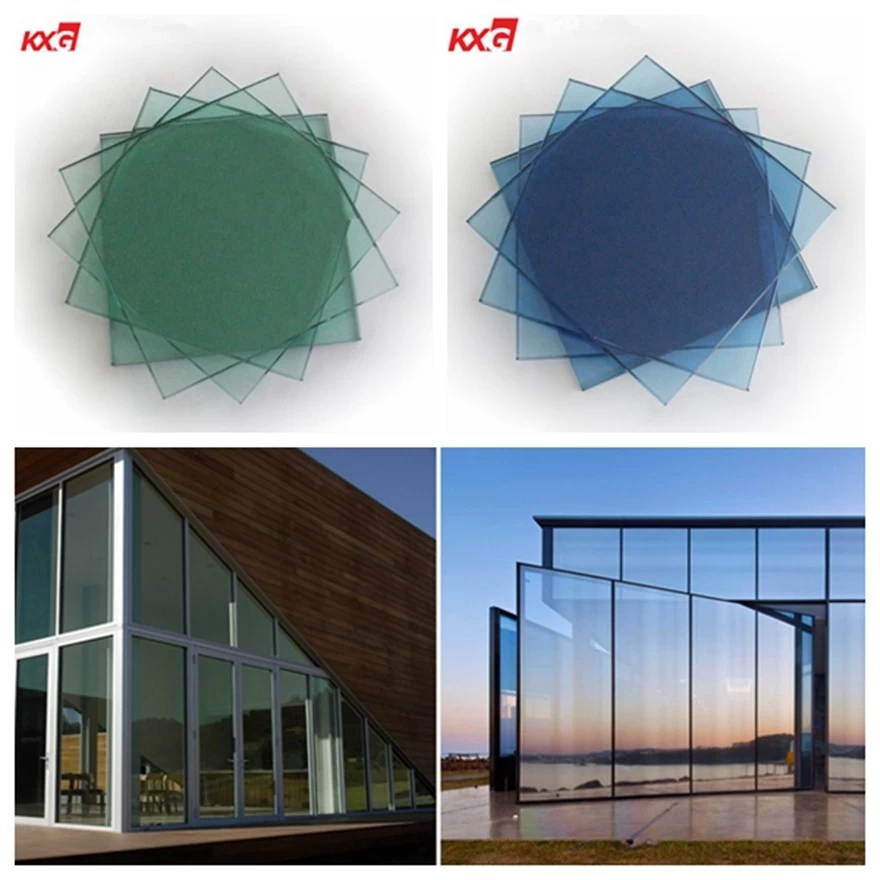

What is Low-E glass? It is formed by coating the glass surface to reduce the glass emissivity E from 0.84 to below 0.15.

Features of Low-E glass:

1.Very high far infrared reflective-low heat transfer.coefficient U value,excellent insulation properties.

2.Its thermal insulation characteristics make it suitable for cold areas in the north,effectively reducing the energy consumption of heating.

What is the type of coated glass process?

Generally there are two types: online coating, offline coating

In-line coated glass is manufactured on a float glass production line. This type of glass has a single variety, poor color uniformity, and poor energy-saving performance. The advantage is that the manufacturing cost is low and can be hot-bent.

Offline coating, rich in variety, uniform color, excellent heat reflection performance, and obvious energy-saving characteristics. The disadvantage is that it cannot be hot-bent.

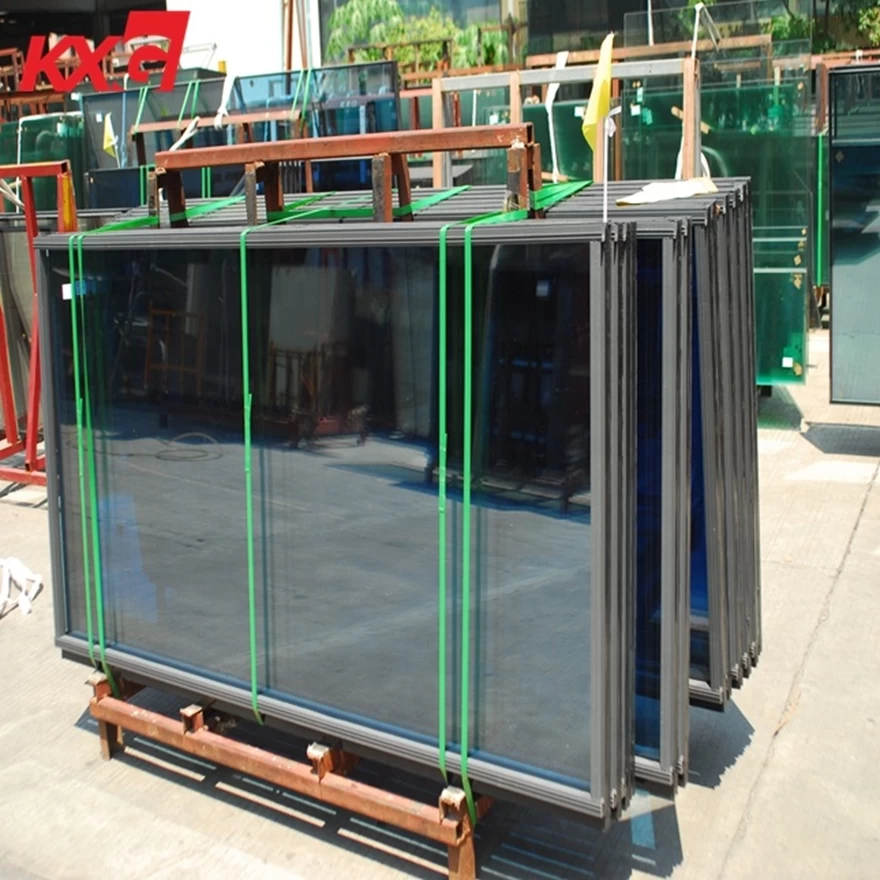

Can LOW-E glass be used as a single piece?

The LOW-E glass manufactured by offline coating cannot be used as a single piece, and can only be used in the synthesis of insulating glass or laminated glass.

Which surface of the insulating glass is most suitable for the LOW-E film?

The hollow glass has 4 surfaces, and the numbers from outdoor to indoor are 1#, 2#, 3#, 4# surface. We suggest: In areas where heating demand exceeds cold demand (in the north), the LOW-E film layer should be on the 3# surface. Conversely, in areas where the cooling demand exceeds the heating demand (southern area), the LOW-E film layer should be located on the 2nd surface.

Do customers need to maintain LOW-E glass products?

Not required! Because the LOW-E film is sealed in the middle of insulating glass or laminated glass, it does not require maintenance, just keep the glass surface clean.