Track the production process of tempered glass

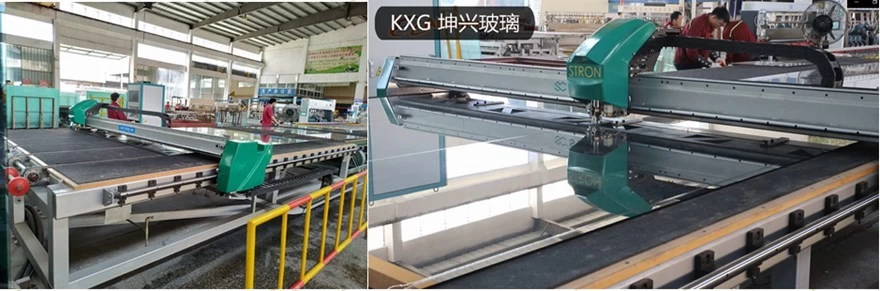

1. Cutting

First, it is the cutting of the float glass. We need to cut the glass into the size that the customer needs.

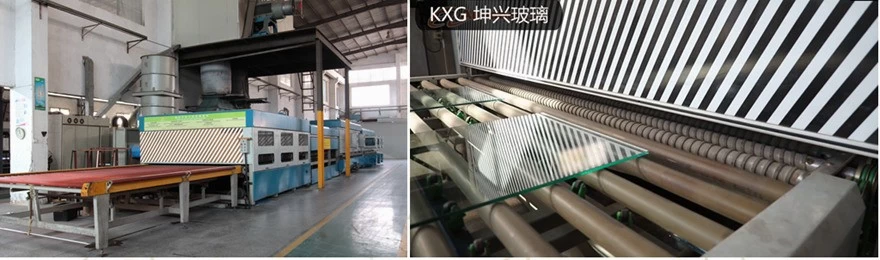

2. Edge grinding

After the cutting is completed, the edge of the glass is sharp, and we need to edging and polishing the edges of the glass.

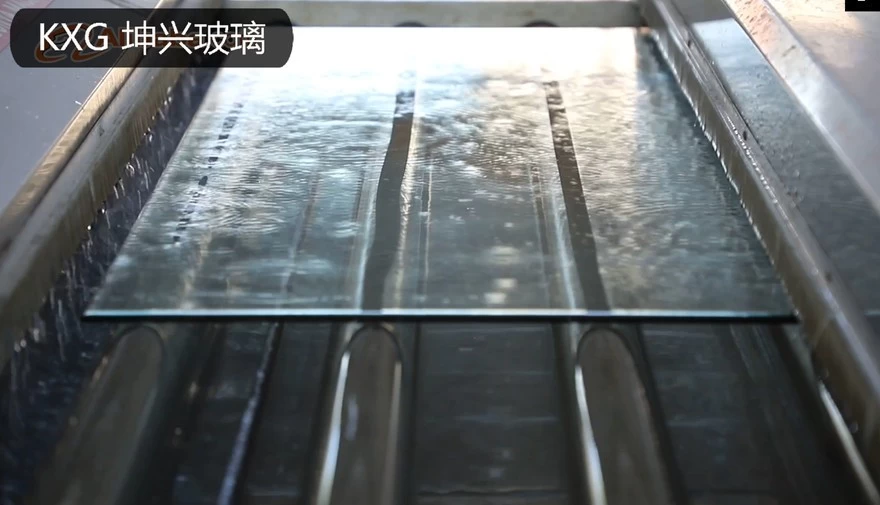

3. Cleaning

After the edging is completed, the glass needs to be cleaned to keep the glass surface clean. Our factory's automatic cleaning machine, fully automatic, intelligent cleaning glass.

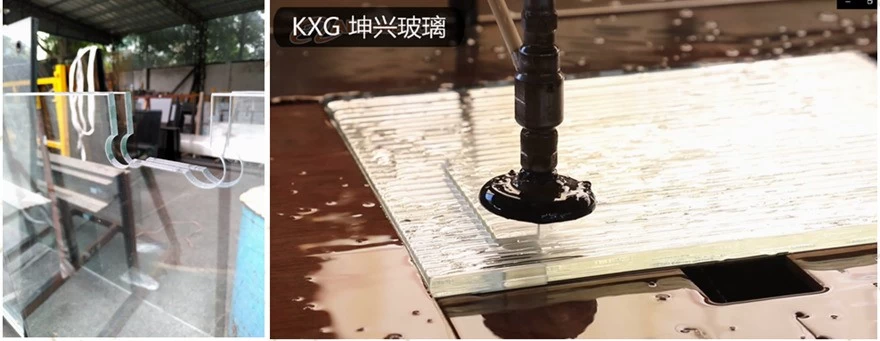

4. Water jet cutting

Our factory can cut glass with high-pressure water flow under the control of computer, and can cut various shapes of gaps according to customers' requirements. Need to clean the glass after the cutting is completed

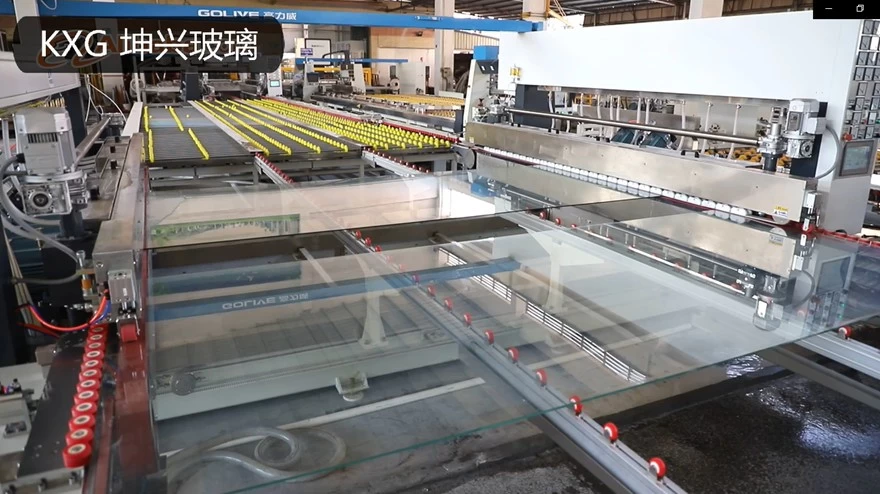

5. Drilling hole

Through the automatic drilling machine, the glass is drilled according to customer requirements. After the drilling is completed, it is necessary to clean the glass again with an automatic cleaning machine.

6. Tempering

After the above steps are completed, the glass can be tempered with a tempering furnace.

More detailed processes can watch the tempered glass video of our factory