Five Key Elements for Controlling the Quality of Insulated Glass

Since the use of insulating glass, its production has gone through processes such as double glazing, simple double glazing, manual single-pass sealing, double-pass sealing, and the composite strip-type insulating glass that has appeared in recent years. After nearly forty years of development, the insulating glass market has gradually matured. As my country attaches great importance to building energy conservation, the quality of insulating glass has become the focus of attention. How to make high-quality insulating glass?

At present, there are three main types of insulating glass in China: 1. Slot aluminum single channel sealing; 2. Trough aluminum double channel seal; 3. Composite sealant strip type insulating glass.

Building insulated glass factory wholesale

Grooved aluminum single-channel sealing has poor sealing performance and is prone to moisture entry, causing condensation and frost on the glass and short service life, so this type of insulating glass is gradually being eliminated. The raw materials of the latter two types of insulating glass are mainly: glass, aluminum strips, butyl rubber, polysulfide rubber or silicone rubber, desiccant, and composite sealing strips.

5 key factors affecting the quality of insulating glass

1. Selection of glass

The glass used to make insulating glass can be transparent tempered glass, coated tempered glass, tinted tempered glass, laminated glass, etc. The above glass pieces must meet the requirements of the corresponding standards, and can only be used after passing the toughened inspection.

The glass-cutting size should be strictly implemented according to the drawing requirements. At the same time, the operator should pay attention to the glass surface and there should be no obvious defects such as scratches and bubbles.

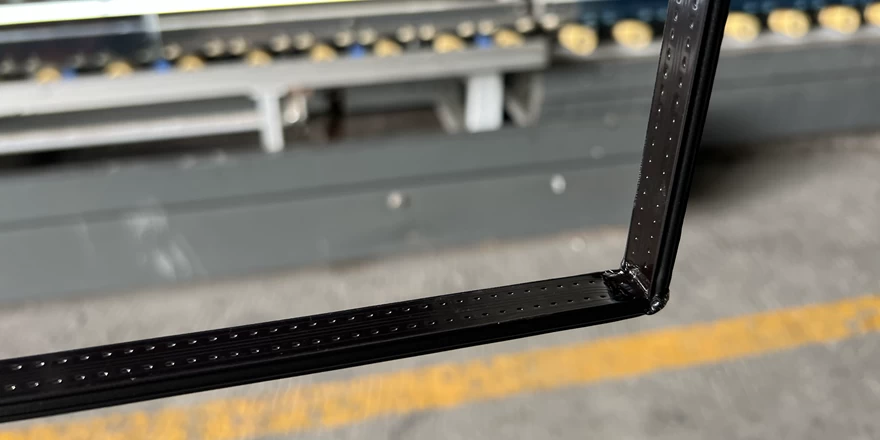

2. Selection of aluminum strips

The thickness of the aluminum strip should be between 0.3-0.35mm, the consistency should be uniform, and the ventilation holes should be evenly distributed. Aluminum bars must be of good quality and high grade. Improve the utilization rate of aluminum strips.

3. Use of desiccant

Currently, there are three main types of desiccants used for insulating glass:

It has a better ability to absorb volatile matter; it has the lowest adsorption capacity for inert gases; it is an ordinary molecular sieve.

Users should choose the appropriate molecular sieve according to their own needs. At the same time, the molecular sieve must have a suitable particle size (1mm-2mm) and hardness. In addition, the environment where molecular sieves are used must be dry, and the filled molecules should be used within 1.5 hours to ensure the quality of the insulating glass.

4、 Selection of sealant

Butyl adhesive: Butyl adhesive is the first seal for aluminum strip-type insulating glass. It is a hot melt adhesive with a low water vapor transmission rate (the lowest in insulating glass adhesive) and high viscosity. It is the most effective barrier for blocking water vapor between the side of the aluminum strip and the glass, but it needs to be heated, pressurized, and extruded by a dedicated machine to be coated on both sides of the aluminum strip. At present, there are many manufacturers of butyl rubber, but the heating temperature and pressure of each manufacturer's rubber are not the same. Some manufacturers' butyl rubber cannot even be machine coated, often interrupted due to impurities. This requires users to choose high-quality products and understand their usage requirements clearly.

Curtain wall double glazing glass supplier

Polysulfide adhesive: Polysulfide adhesive is currently the largest type of sealant used in insulating glass. Polysulfide adhesive has good oil resistance, solubility resistance, and sealing properties. Polysulfide adhesive should have metal oxides as curing agents for polymerization. Requirements for the selection of polysulfide adhesive: the color difference between the two components is distinct. Valid for more than six months; Strong UV resistance; Has good fluidity and curing elasticity.

Silicone sealant: Silicone sealant has structural properties, aging resistance, and UV resistance, but its main weakness is its high water vapor transmission rate. Therefore, silicon cave adhesive is suitable for places with strong lighting and poor environments, such as glass curtain walls, and butyl adhesive must be used as the first seal. In the past, China relied on imports for a long time for silicone adhesive. Now, the State Economic and Trade Commission has established a leadership group for silicone adhesives to conduct safety certification for structural adhesives. At present, multiple domestic enterprises have passed certification.

5、 The use of composite sealant strips

Composite sealant strip is a composite sealing material developed by American chemists in the 1980s. It is a hollow glass raw material that integrates support framework (corrugated aluminum strip), sealing (butyl rubber), and drying (desiccant). Its biggest advantages are simple operation process, less waste of raw materials, fewer personnel, low management cost, and good operating environment; The disadvantage is that the adhesive strip absorbs moisture slowly and requires specialized equipment. At present, the price of adhesive strips is relatively high due to production limitations. The selection of composite sealant strips should consider surface smoothness, aluminum strip quality, adhesive content, and moderate viscosity.

Building wall safety glass window door manufacturer

The industrial method suitable for insulating glass is to use aluminum strip butyl adhesive as the first seal, which has low water vapor permeability, strong adhesion, and strong sealing performance against inert gases and water molecules. Silicone structural adhesive as the second seal can be used in places with strong light and poor environment, such as glass curtain walls, doors and windows, and facades.