Tempered Glass: Transformation From Ordinary To Extraordinary

There is a type of glass that can withstand greater external forces than conventional glass, and even if broken, it will not form sharp fragments, building a solid safety barrier for us. It is tempered glass known as the "safety shield".

The "Extraordinary Features" of Tempered Glass

Tempered glass, also known as strengthened glass, is made by physically or chemically treating float glass or glass products to produce evenly distributed permanent stress on the glass surface layer, thereby achieving high strength and high thermal stability.

Impact resistance: The impact resistance of tempered glass is about 4 to 5 times that of ordinary glass. It can effectively cope with the impact of heavy objects or external pressure and is not easily broken. When used as building partitions, doors, and windows, it can maintain structural integrity and ensure indoor safety.

Safety: After broken into small obtuse-angle particles, it can reduce harm to the human body. The production process of tempered glass puts it in a state of internal compression and external tension after the production is completed. The evenly distributed tensile stress inside allows the tempered glass to form small obtuse-angle particles even if it break, which is different from the sharp particles formed after ordinary glass breaks. fragments. Used in schools, hospitals, shopping malls, and other places, it can greatly reduce threats to personal safety.

Strong thermal stability: the temperature difference it can withstand is 2.5 to 3 times that of ordinary glass. It shows good physical stability in high-temperature environments, so it is also widely used in kitchen doors, partitions, and cabinets, providing better safety protection for the cooking process.

safety toughened glass manufacturer

Tempered glass production process

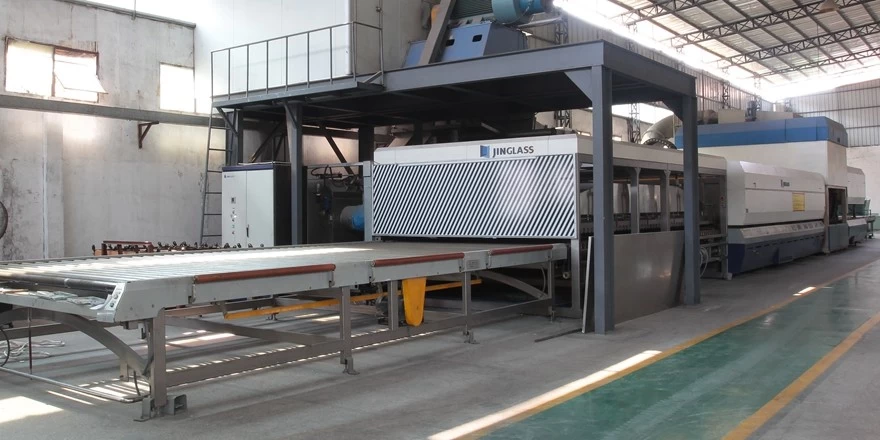

After ordinary glass undergoes pre-treatment processes such as cutting, edge grinding, washing, and drying, it is sent to the tempering furnace for processing. In the tempering furnace, the glass first passes through the preheating zone to increase the surface temperature of the glass; then it enters the heating zone to make the glass surface reach the softening point; finally, the glass is quickly sent to the cooling zone. In the cooling zone, high-pressure fans quickly blow cold air onto the glass surface to cool the glass. During this process, compressive stress is formed on the surface of the glass and tensile stress is formed inside, thereby significantly enhancing the strength and impact resistance of the glass.

clear glass bathroom door supplier

Tempering method of tempered glass

Glass tempering is mainly divided into physical tempering and chemical tempering.

Physical tempering, also known as quench tempering, is a process whereby glass is heated to a specific temperature and then rapidly cooled at a preset rate. This process creates compressive stress on the glass surface, significantly improving the mechanical properties of silicate glass. Usually suitable for larger and thicker glass above 3mm, such as building and automotive glass.

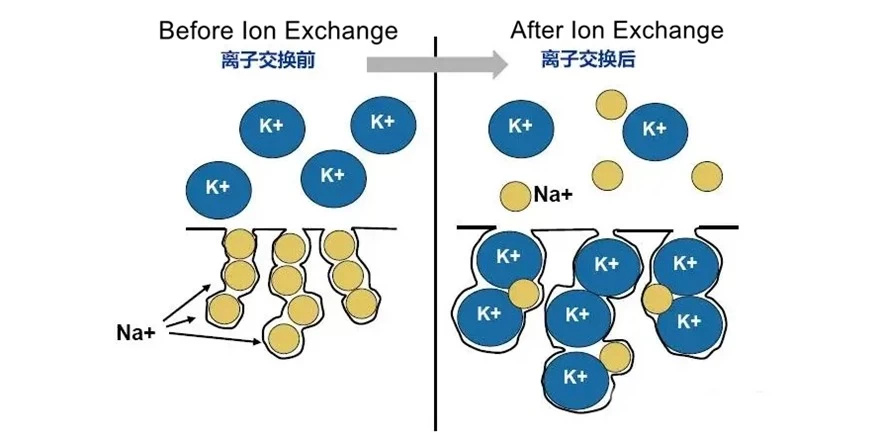

Chemical tempering uses an ion exchange method to replace sodium ions with a smaller radius on the surface of the glass with ions with a larger radius such as potassium ions and cesium ions, causing compressive stress to form on the surface of the glass, greatly improving the mechanical properties and strength of the glass. This processing method is mainly suitable for thin glass with a thickness of less than 1mm, glass requiring high precision, or complex shapes, such as lenses, aviation glass, electronic substrate glass, etc.

The process operation has an extremely important impact on the quality and subsequent normal use of tempered glass products. KXG strictly controls and finely operates every process link to ensure that building tempered glass products have excellent performance and stable quality, thereby meeting the needs of various application scenarios.