Why insulating glass fails

As an energy-saving building material, insulating glass is widely used for its good thermal and acoustic insulation properties. The high or low dew point of insulating glass reflects the quality of insulating glass.

Insulating glass in the process of use, when the ambient temperature decreases to the point that the temperature of the glass surface is reduced to the dew point within the dry air layer, the surface of the dry air layer will produce condensation or frost. Due to the condensation or frost on the inner surface of the glass and affect the insulating glass performance. The air layer is not condensed above -40℃, then the insulating glass is not condensed in the air layer during use.

1.Analysis of the causes of dew point rise

The dew point of insulating glass is the temperature at which the humidity of the air sealed in the air layer reaches saturation. Below this temperature, the water vapor in the air layer will condense into liquid water. Can be launched: the higher the content of water, the higher the dew point temperature of the air, when the temperature of the inner surface of the glass is lower than the dew point of the air in the air layer, the moisture in the air will condense or frost on the inner surface of the glass.

The rise in dew point of insulating glass is caused by outside moisture entering the air layer without being absorbed by the desiccant, and there are three possible causes of dew point rise.

(1) Air bubbles in the sealant, causing air moisture to enter.

(2) Moisture enters into the air layer through polymer diffusion.

(3) The effective adsorption capacity of desiccant is low.

2. Insulating glass dew point control measures

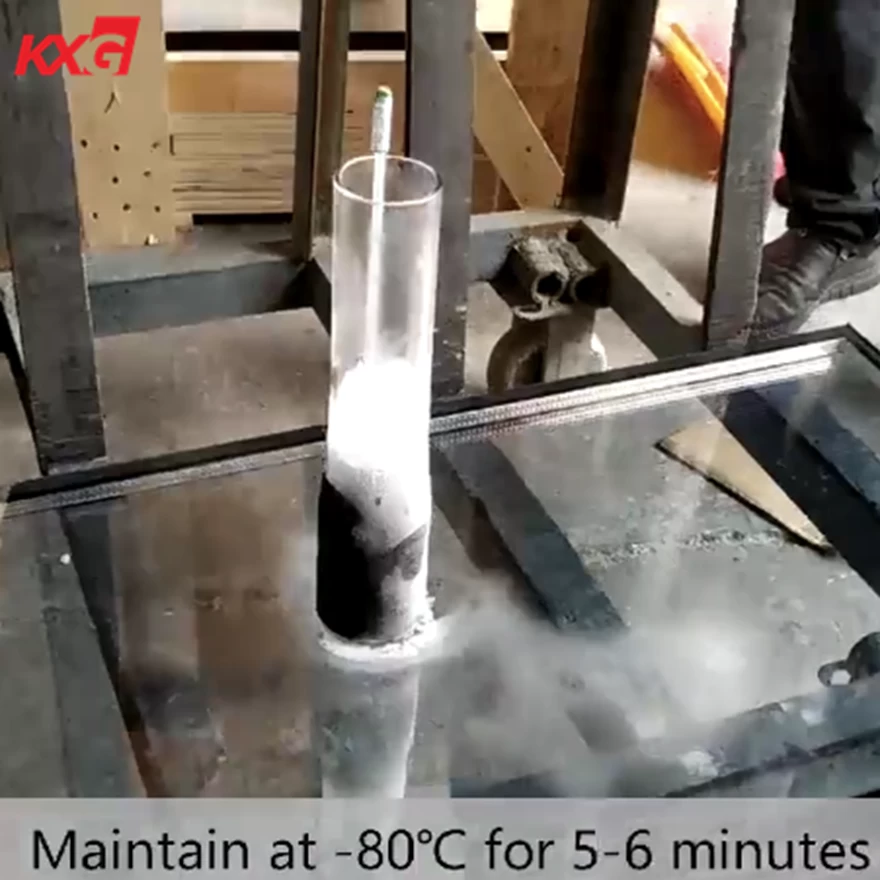

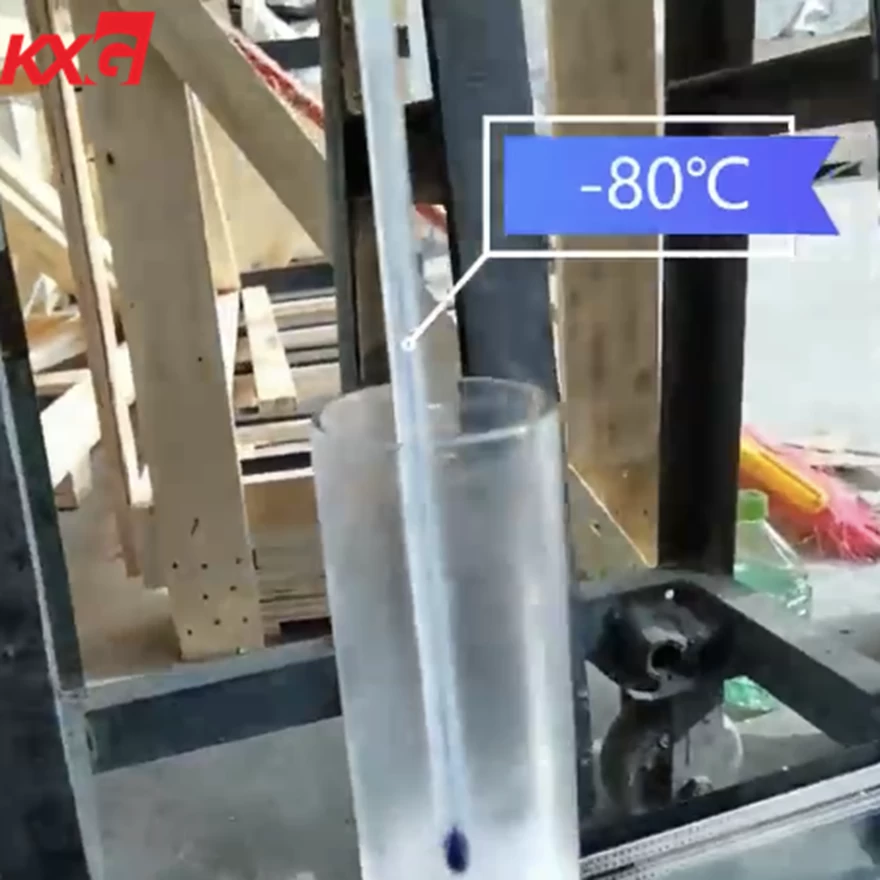

(1) Dew point test

Our factory can reach -70℃.

(2) Reduce the production process time

Reduce the contact time between desiccant and atmosphere, reduce the loss of adsorption capacity and make the desiccant have higher adsorption capacity.

(3) Select suitable desiccant

To choose desiccant with high and long-lasting adsorption rate.

(4) the production process of insulating glass has strict requirements for the environmental humidity, in the current production process, but also filled with inert gas to replace the air to improve thermal insulation properties and reduce the dew point.